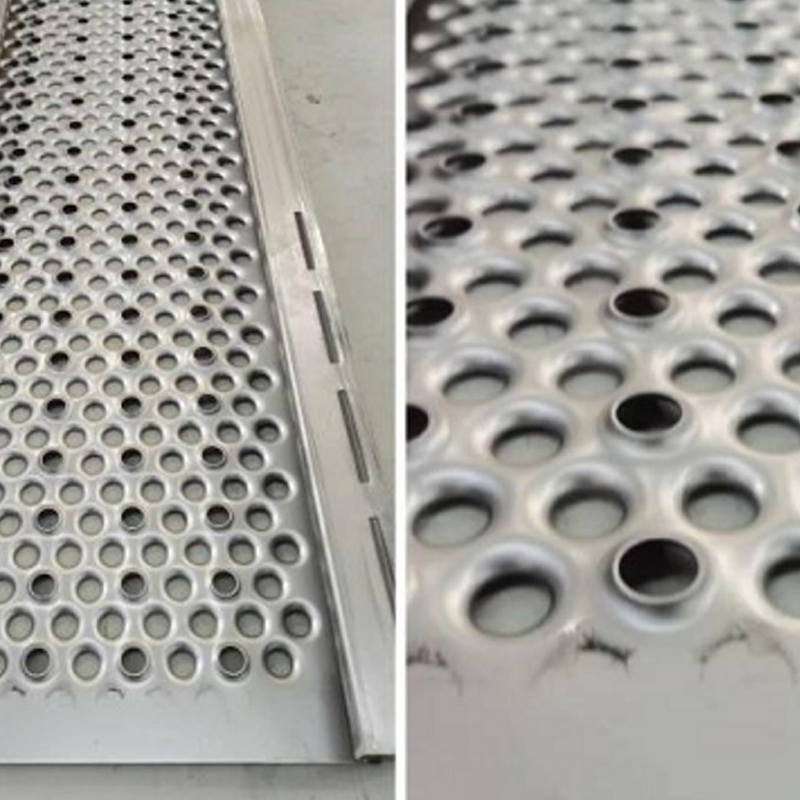

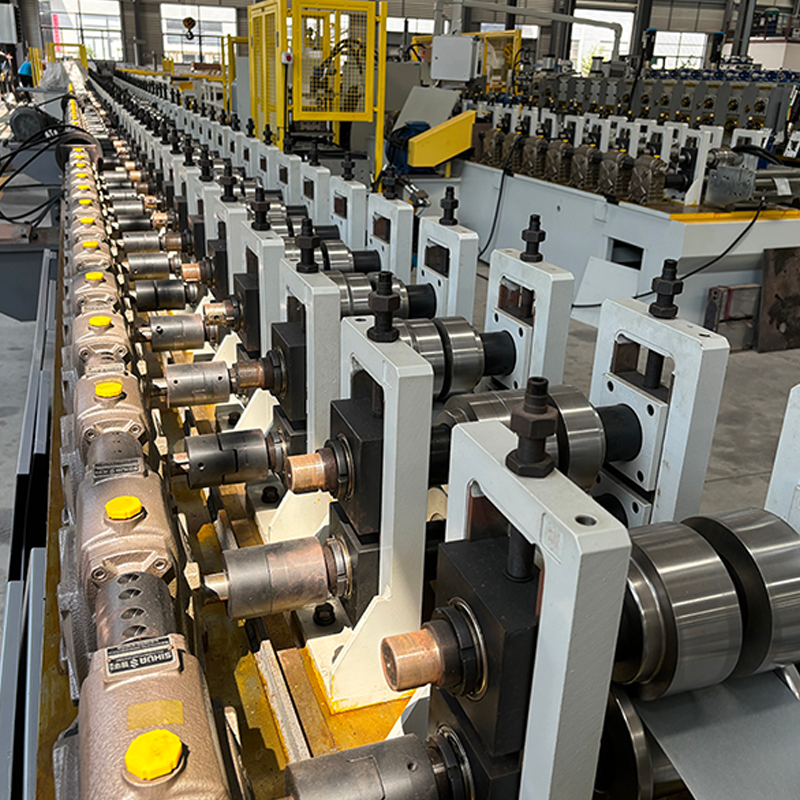

Shanghai SIHUA is a professional manufacturer dedicated to researching and developing automatic high-speed flying shear roll forming machines. Our main products include ceiling t-grid roll forming machine, drywall profiles light steel roll forming machine, strut channel roll forming machine, upright rack roll forming machine, cable tray roll forming machine, scaffolding deck heavy steel roll forming machine, metal profile automatic packaging machine, customized machine, and automotive high-strength steel roll forming machine.

The Shanghai headquarters has a high-standard talent team that leads the company to innovate continually. SIHUA is a high-tech enterprise specializing in precision and innovation in Shanghai, holding 42 utility model patents and 11 invention patents.