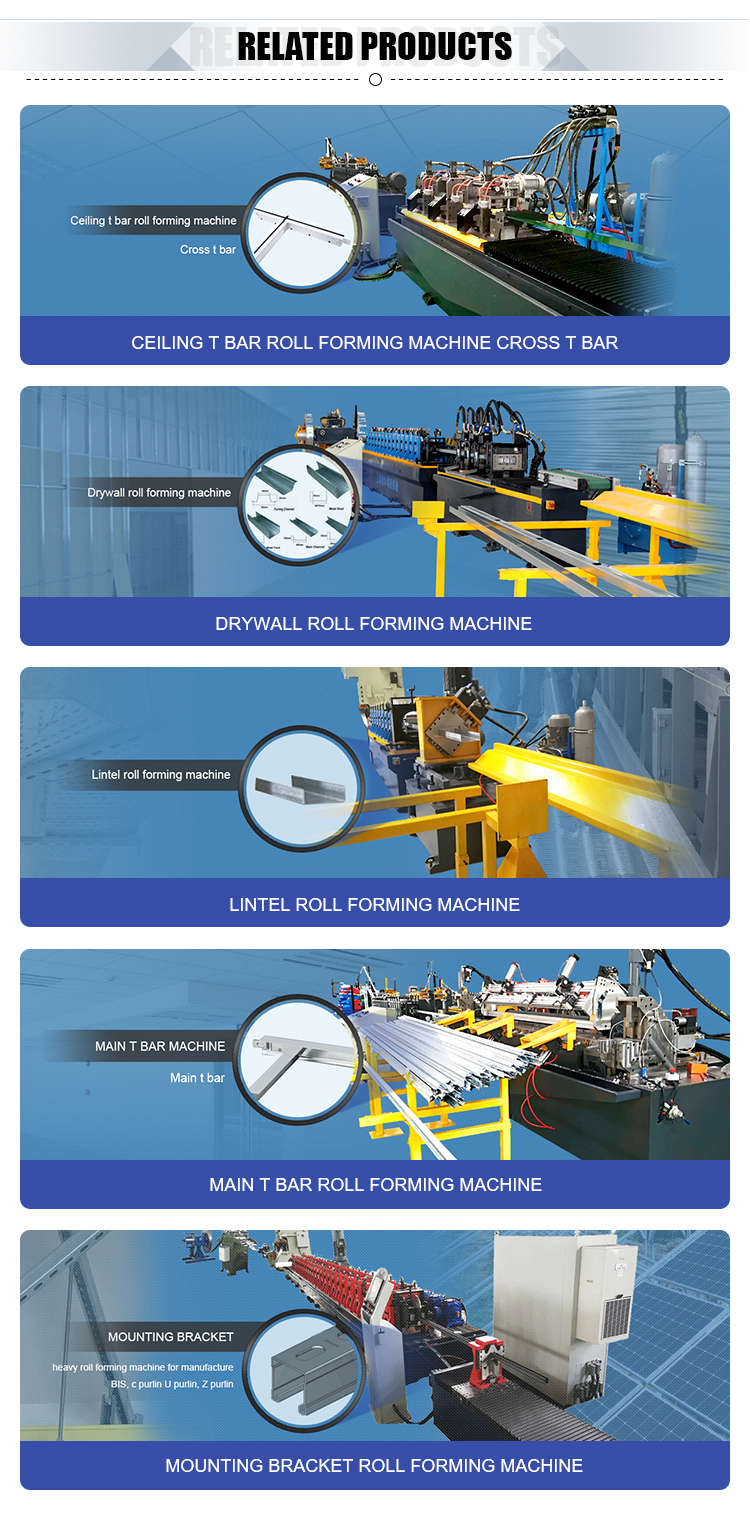

Home > Ceiling T Bar Roll Forming Machine

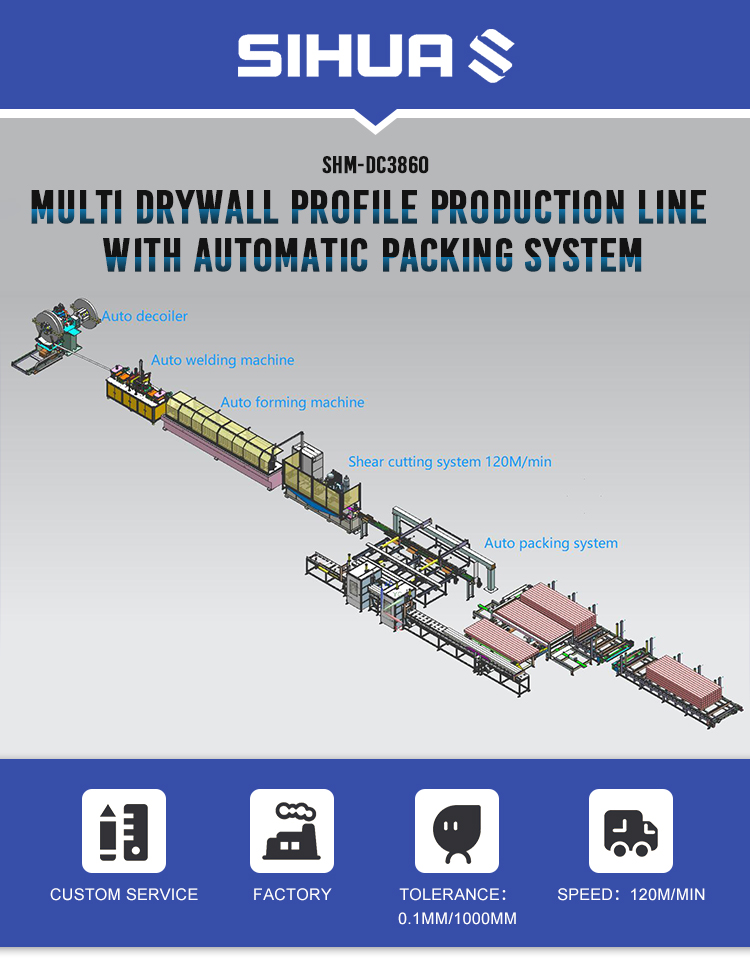

1.1、T-Bar production line can be monitored by PLC. If the T-bar production line has errors, the PLC will locate the errors. It is easy to maintenance for workers.

1.2、Cross T-Bar Production speed :

1.2.1: 4`=1 minute to produce 30PC.

1.2.2: 2`=1 minute to produce 60PC.

1.3、The machine can produce product specifications :26*24cross-T.Different specifications exchange COMBI can be replaced in 30 minutes,

For example :26H *24 specifications can be produced if add one set COMBI

1.4 Electric power:40kw

Voltage: 380v/400v/415v 3-phase 50/60hz or as custom need

| Automatic high speed long and short cross t bar and wall angle roll forming making machine | |||

| No | Item | Unit | Qty |

| 1 | Double hydraulic de-coiler(paint steel coil) | No | 1 |

| 2 | Storage unit for paint steel | No | 1 |

| 3 | Double hydraulic de-coiler(galvanized steel coil) | No | 1 |

| 4 | Storage unit for galvanized steel | No | 1 |

| 5 | Cross t bar roller forming units. Gear box COMBI | No | 1 |

| 6 | Triple sizes profile cleaning unit | No | 1 |

| 7 | Cutting table base | No | 1 |

| 8 | Cutting dies | No | 3 |

| 9 | Riveting machine for Alloy joints of T-bar Products (buyer provide die) | No | 1 |

| 10 | Packaging platform | No | 1 |

| 11 | Big Control panel(Electric control system) with air conditoner Big control cabinet Air conditioner one set | No | 1 |

| 12 | Hydraulic station Using Servo motor 5HP chiller | No | 2 |

| 13 | Safe fence | No | 1 |

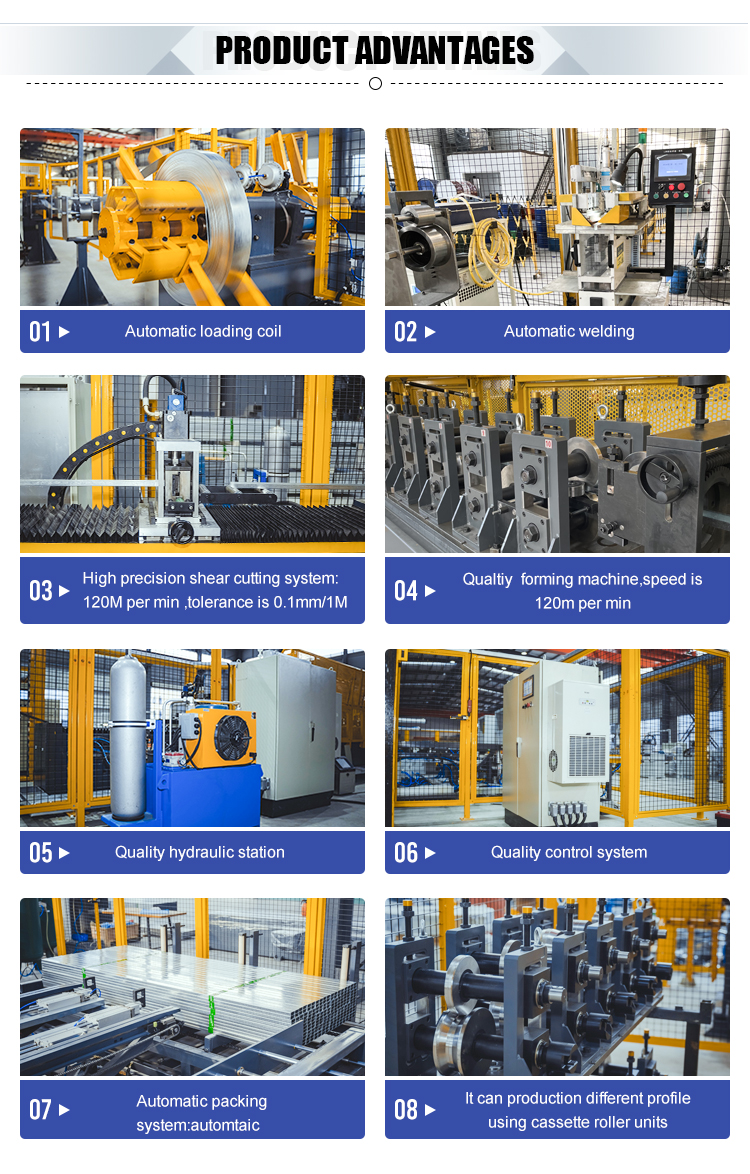

12.1, Motor power: 15KW, Motor brands: Inovance. 12.2, Pump working pressure: 140 kg Hydraulic flow: 80L Brand is ECKERLE(Germany). 12.3, oil cylinders, quantity: 6 pieces 12.4, Accumulator:40L Brand: OLAER(French) 12.5, Pressure sensor, IFM (German) The magnetic valve: Rexroth 24V (German). 12.6, Filtration brand is Parker (USA) 12.7, The oil is cooled by air (as customized)

11.1, PLC brands: MITSUBISHI (JAPAN). 11.2, Frequency invertor power:15 KW brand: YASKAWA 11.3, Relay and breaker brand: SCHNEILDER 11.4, Human interface (touch screen) brand: KINCO, size 10.4 ". 11.5, Electric cabinet, uses the quick plug to connect outside wire. 11.6. Shear controller, brand: SI HUA (import from German). 11.7 Encode is OMRON

3.1 Loading capacity :3000 KGS*2 3.2. Max coil specification: O.D. 1,500 mm. I.D.508 mm. Width: 150 mm. 3.3. By hydraulic rolling in to tighten the coil.

1.1 Loading capacity :1500Kgs*2 1.2. Max coil specification: O.D. 2,000 mm. I.D. 508 mm. Plate width: 100 mm. 1.3. By hydraulic rolling to tighten the coil.

8.1 Quantity of dies are 3 sets :1pieces head cutting+1 pieces tail cutting+1 pieces Medium Hole Die 。 8.2 Die material(Die cutter、Die cutting board ):DC53 Vacuum heat treatment hardness:58-62HRC.

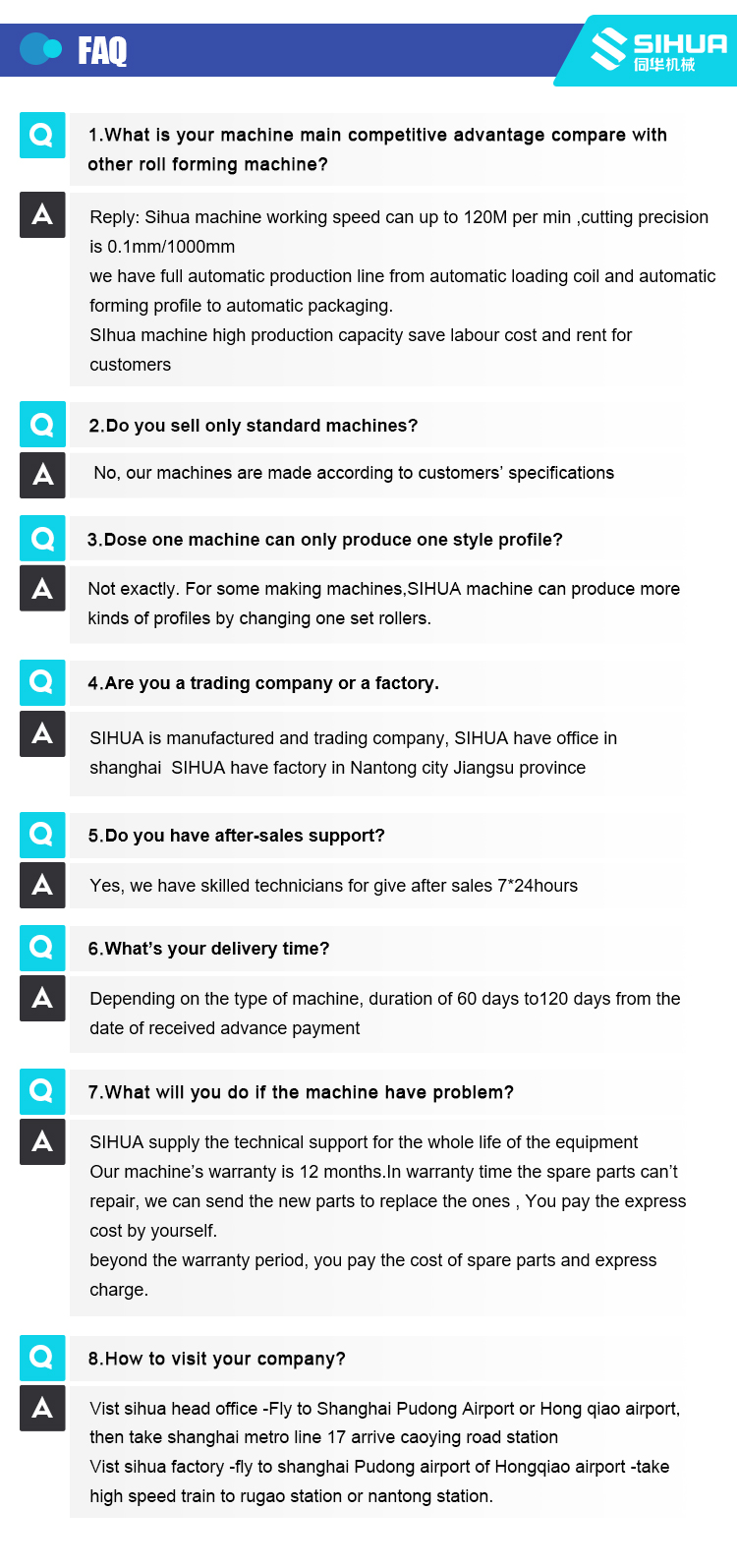

Product drawing:

Main t bar profile 38h *24*3600mm、/3700mm

Cross t bar profile 38h*24*600/1200mm

Product drawing:

Main t bar profile 38h *24*3600mm、/3700mm

Cross t bar profile 38h*24*600/1200mm

Ceiling Main T bar roll forming machine

Ceiling Main T bar roll forming machine

Machinename:SIHUACross-Tbarproductionline.Automatichigh speed high precision longandshortcrosstbarrollformingmachineProductsizes1. 25H*24*1220mm(4`)/12002. 25H*24*610mm(2`)/600 Wedesign

Machinename:SIHUACross-Tbarproductionline.Automatichigh speed high precision longandshortcrosstbarrollformingmachineProductsizes1. 25H*24*1220mm(4`)/12002. 25H*24*610mm(2`)/600 Wedesign