Home > Drywall profile machine

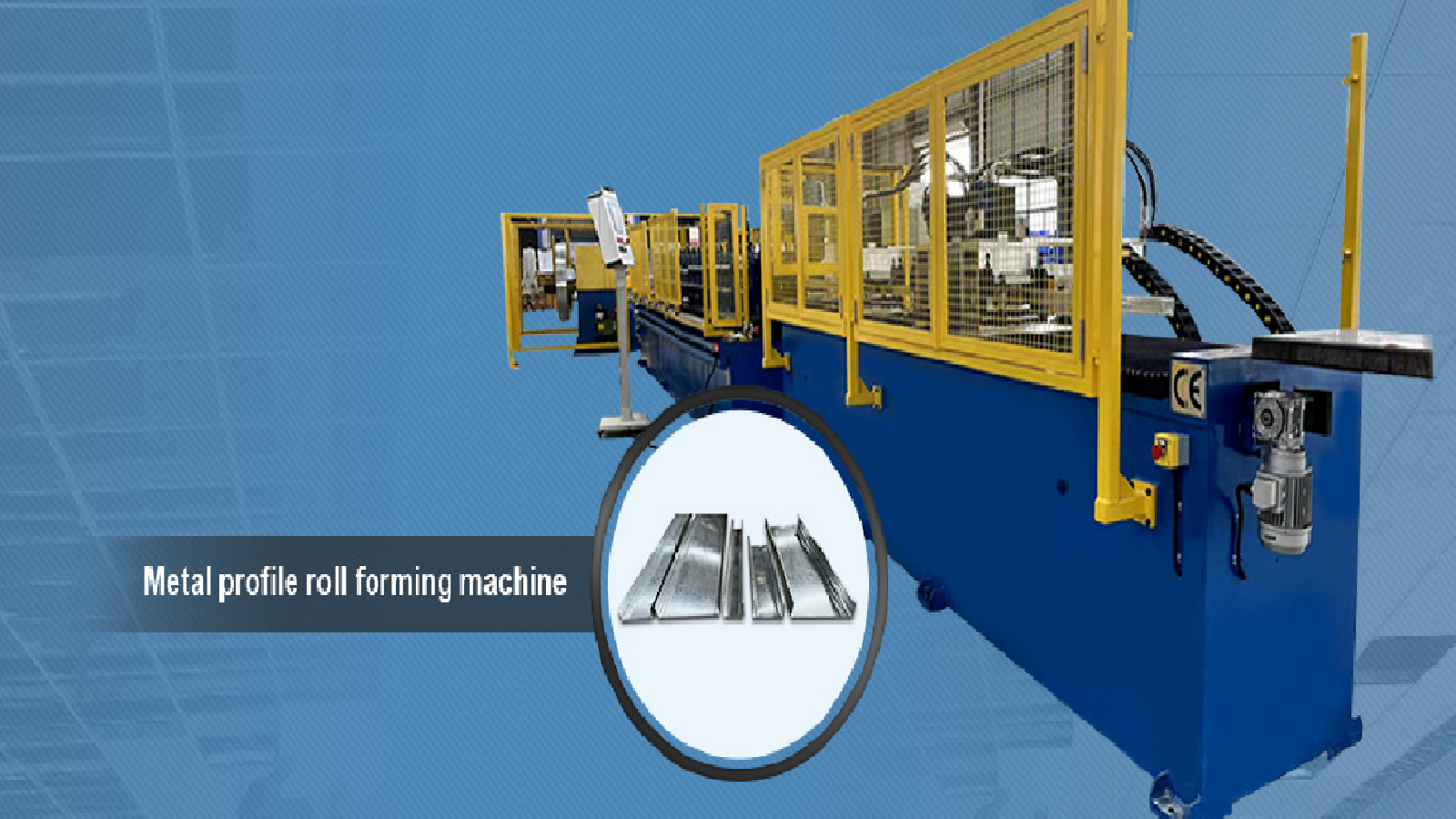

90M per min Automatic Change Stud and Track Roll Forming Machine for produce UW CW_EU and CW_IT

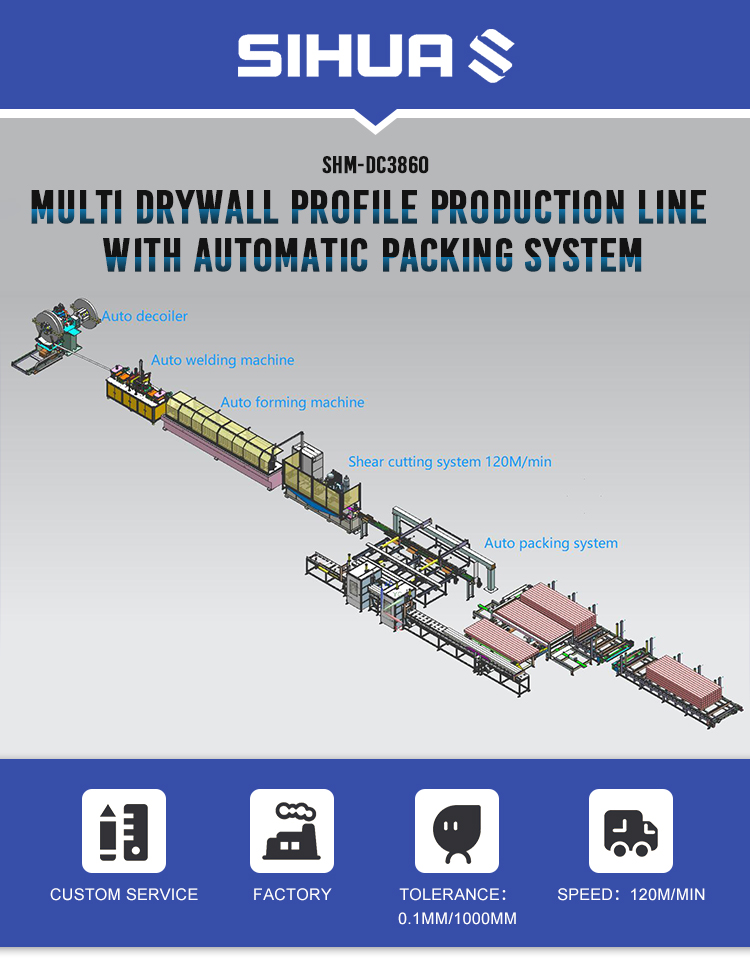

Working flow: Double head hydraulic decoiler- Automatic change roll forming machine- Double shear cutting system-Europe hydraulic station-Big control system control

| Steel Profile Roll-forming Machine | |||

| No | Item | Unit | Qty |

| 1 | Double Head Hydraulic De-Coiler | No | 1 |

| 2.1 | Roll-Forming Machine Base | No | 1 |

| 2.2 | Automatic change profile system | NO | 1 |

| 2.3 | Introduction and Lubricating Unit | No | 1 |

| 7 | Dobule Wagon Cutting and punching Unit | No | 1 |

| 8 | Cutting Dies for UW and CW_EU & Special Cutting Die for CW_IT Profile | No | 1 |

| 9 | Hydraulic Unit | No | 1 |

| 10 | Electric control system (PLC) | No | 1 |

| 11 | Safety Guards, Fences and protection system for all units | LS | 1 |

| 12 | Additional sensors | LS | 1 |

| 13 | Documentation | LS | 1 |

| 14 | CE Certification | LS | 1 |

| 15 | Training | LS | 1 |

Feature: 1.Hydraulic expation 2.Double head 3ton*2pc

Feature: 1. Servo adjust web 2. Servo adjust height

Feature: 1.cutting speed 90m per min 2.Punching speed 80m per min

Feature: Tai wan Hydraulic station

Feature: shear speed is 90M per min tolerance is 0.5mm per 1000mm

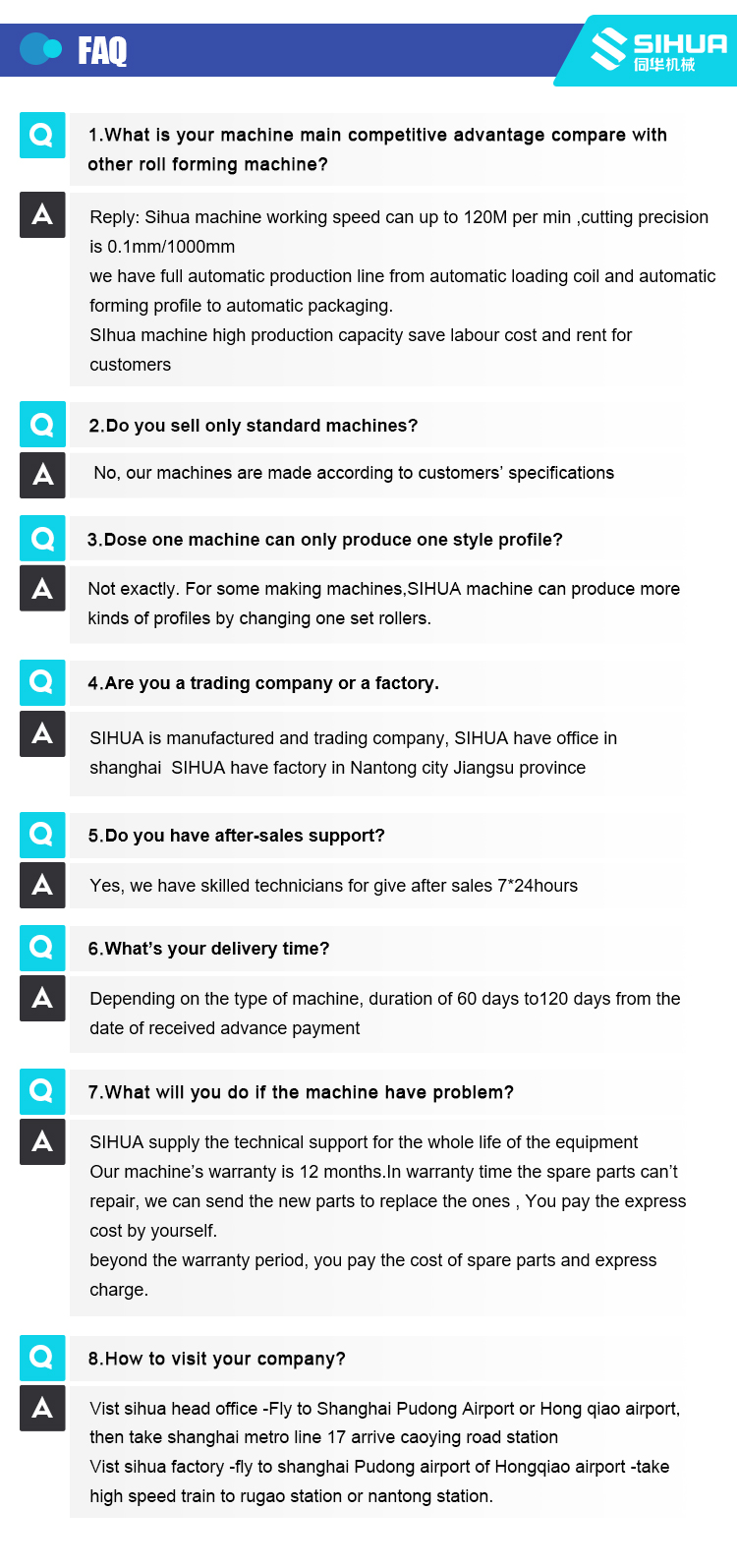

1. Easy to operate

2. High production speed

3. Stable and durable

4. Has a wide range of uses

| Multiple Profil Automatic Change Stud And Track Roll Forming Machine | |

| Model | QCU-AHS90 |

| Profile | EU 50-150 CW_EU 50-150 CW_IT 50-150 |

| Drive system | Reducer |

| Shear system | 2 |

| Shaft diameter | 50mm |

| Wall frame gap | 300mm |

| Cutting Speed | 90M/min |

| Punching speed | 60M/min |

| Material thickness | 0.4-0.9mm |

| Tolerance | 0.5mm |

DRYWALL METAL PROFILES & SPECIFICATIONS STEEL SPECIFICATIONS

Our Metal Sections are manufactured using hot dipped zinc coated steel-Z180 & Z275 STUDS

Studs are the Primary sections used in the Drywall & Lining Systems.Studs used in Vertical condition at appropriate centers to match the structural stability based on the design. Studs are fixed between the Base & Head Track, Screwed only with the Base track & Friction fit at the Head Track.

Material thickness 0.55-1.00mm

Wed size;50/75/100/125/150mm

Flange:34/36mm

Length:3000mm & Customized Length

Deflection Tracks are used at the top as Head Tracks. Which helps to allow the partitions, when needs a movement (up, down) within the structure at the head of a partition. Deflection Tracks Secured with appropriate anchors at Concrete Slab & Hold the studs in position and it helps in aligning the Boards.

Thickness:0.80,&0.90 mm

Width::50,64,70,75,90,100,125&150mm

Flange:50mm

Length::3000mm

Tracks are the Secondary sections used in the Drywall & Lining Systems. Tracks used in Horizontal condition & Secured with appropriate anchors at Floor Slab & Soffit. Tracks Hold the studs in position and it helps in aligning the Boards.

Thickness:0.55,0.60,0.80,0.90,1.20 & 1.50 mm :

Witth :50,64,70,75,90,100,125 & 150 mm

Flange:30mm

Length:3000mm

stud and track profile roll forming machine which can produce 50/75/100/125/150mm web stud and track profile

stud and track profile roll forming machine which can produce 50/75/100/125/150mm web stud and track profile

SIHUAProfessonalhighspeedhighprecsionstudandtrackrollformingmachinepopularsellinmanycountries,commonthicknessbetween0.4-0.9mm,Thismachinecuttingoffspeedis120Mpermin,Punchingholespeedis80MPermin,the120Mperminma

SIHUAProfessonalhighspeedhighprecsionstudandtrackrollformingmachinepopularsellinmanycountries,commonthicknessbetween0.4-0.9mm,Thismachinecuttingoffspeedis120Mpermin,Punchingholespeedis80MPermin,the120Mperminma

Working speed is 90M per min shear cutting off stud and track roll forming machine

Working speed is 90M per min shear cutting off stud and track roll forming machine