Home > Struct Roll Forming Machine

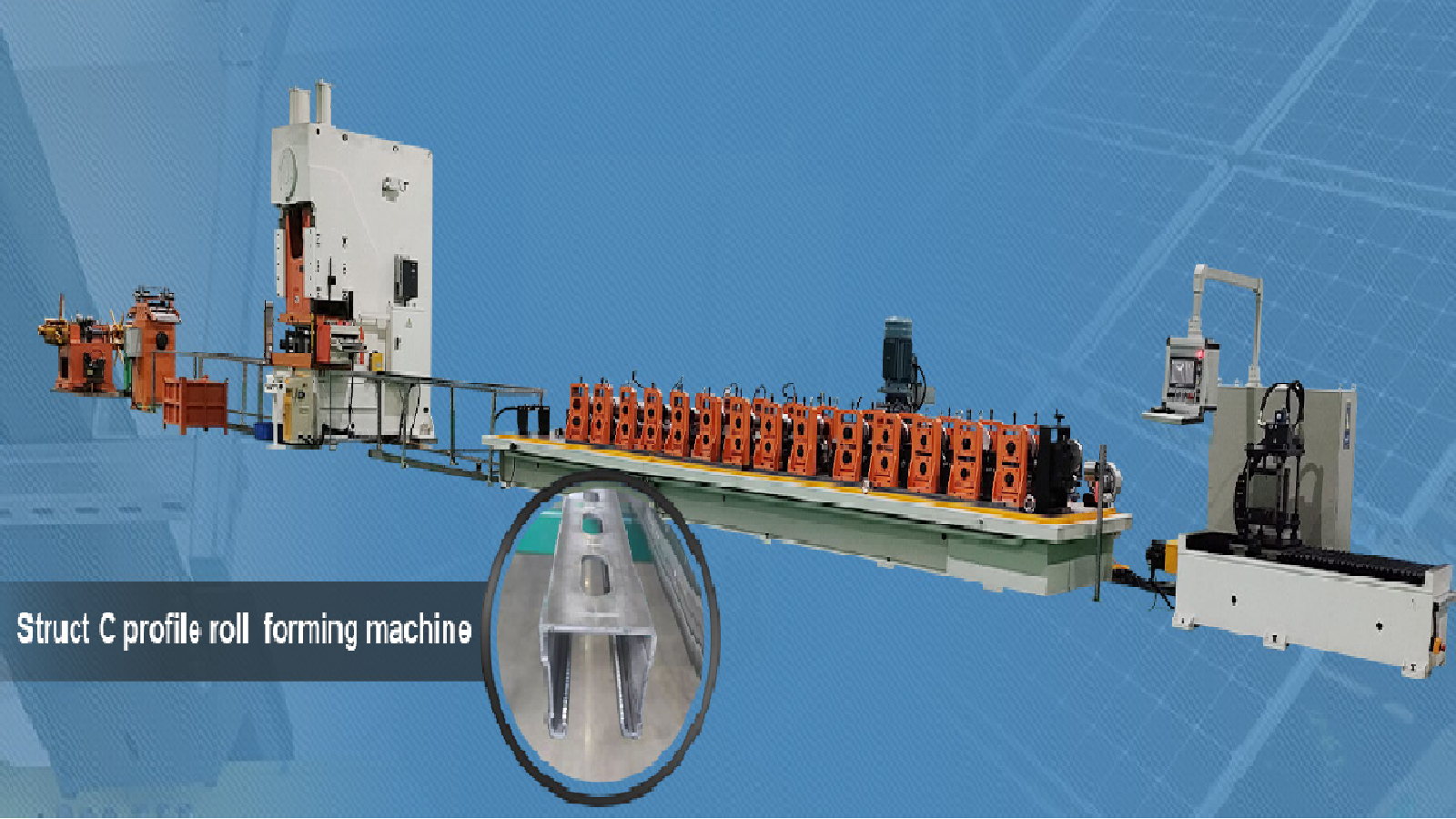

C profiles drawing

C RAIL material thickness 2.0 mm

Production speed

Product speed is 30Mper min -20M/min Product thickness is 1mm-2.00mm-2.5.00mm

Product length tolerance L+-1mm

Total power:45.4kw

Voltage: 380v 3-phase 50hz | Motor in roll forming machine:30KW*1PC | Motor in hydraulic station | power is 11kw | Servo motor is 4.4kw

Introduction

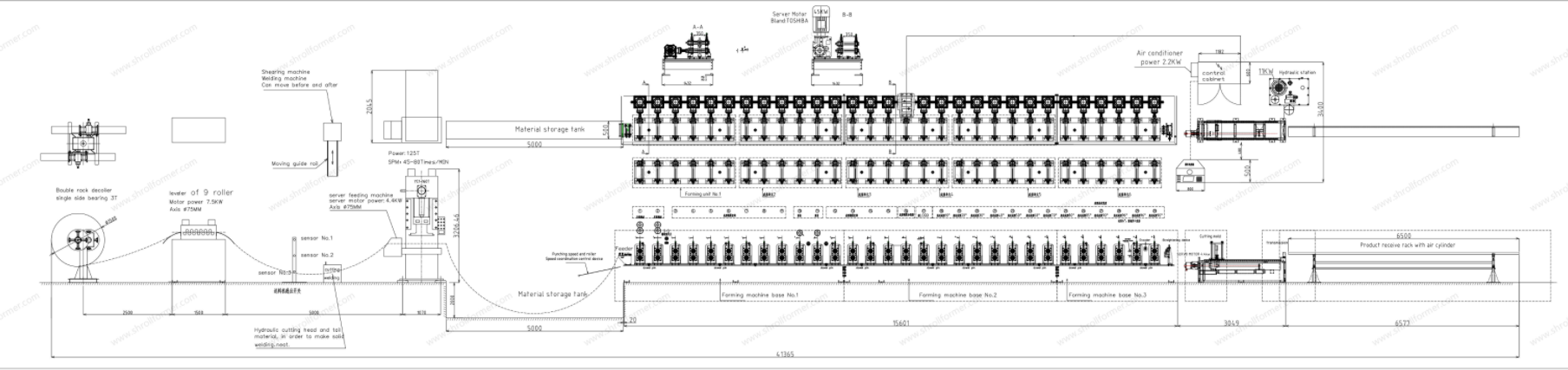

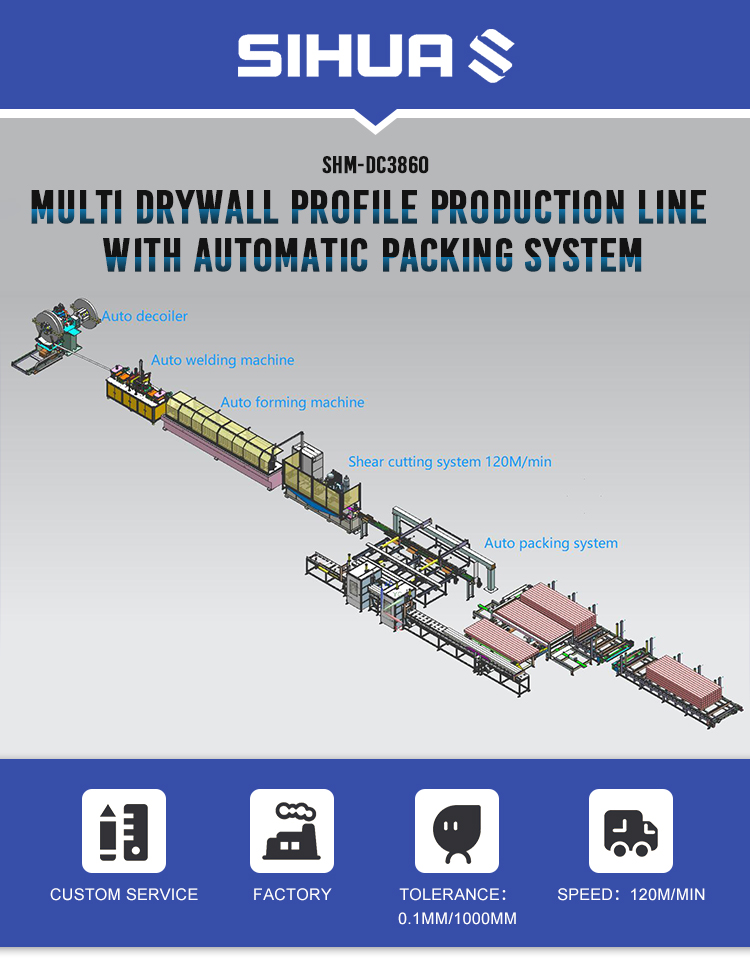

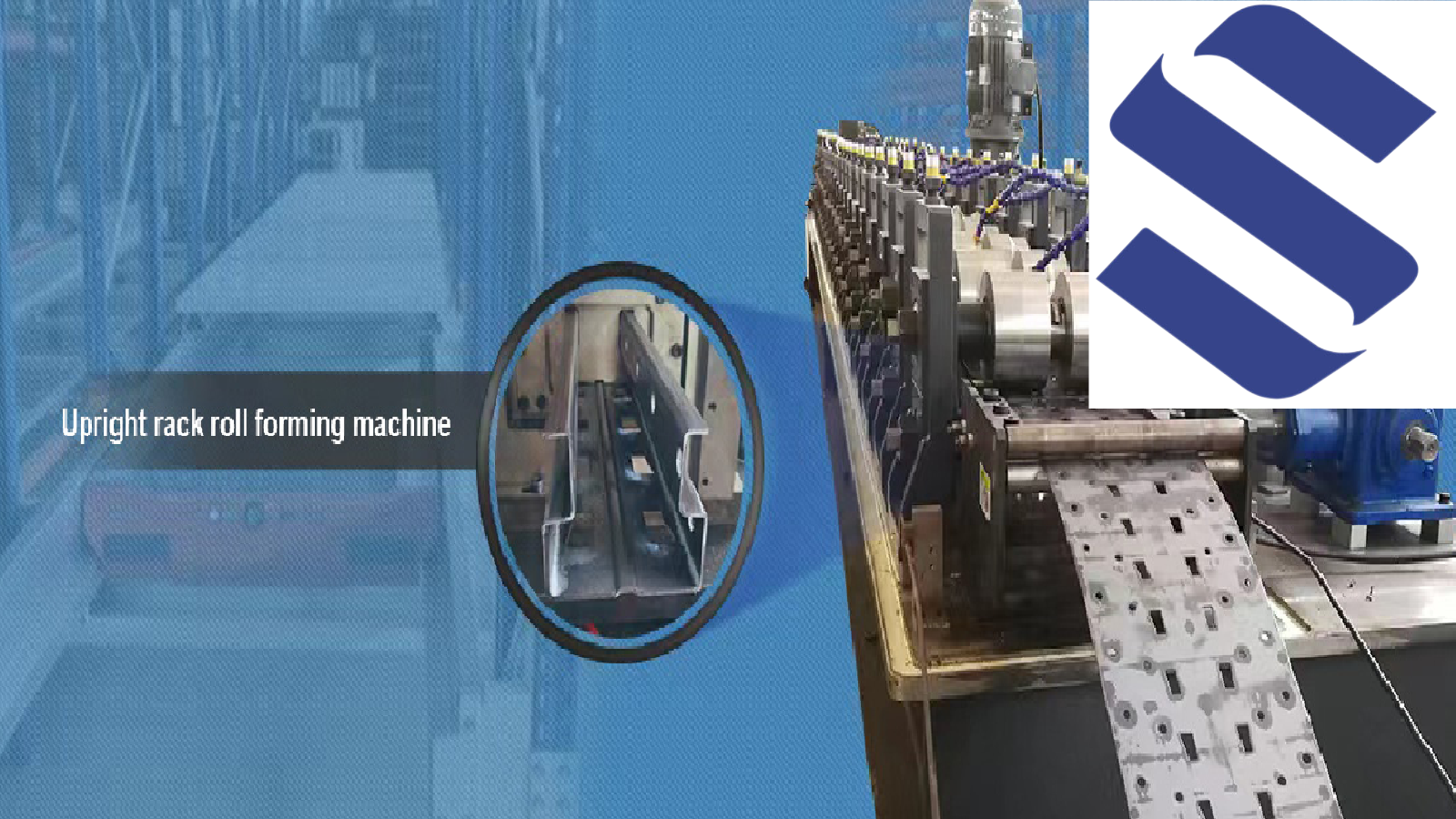

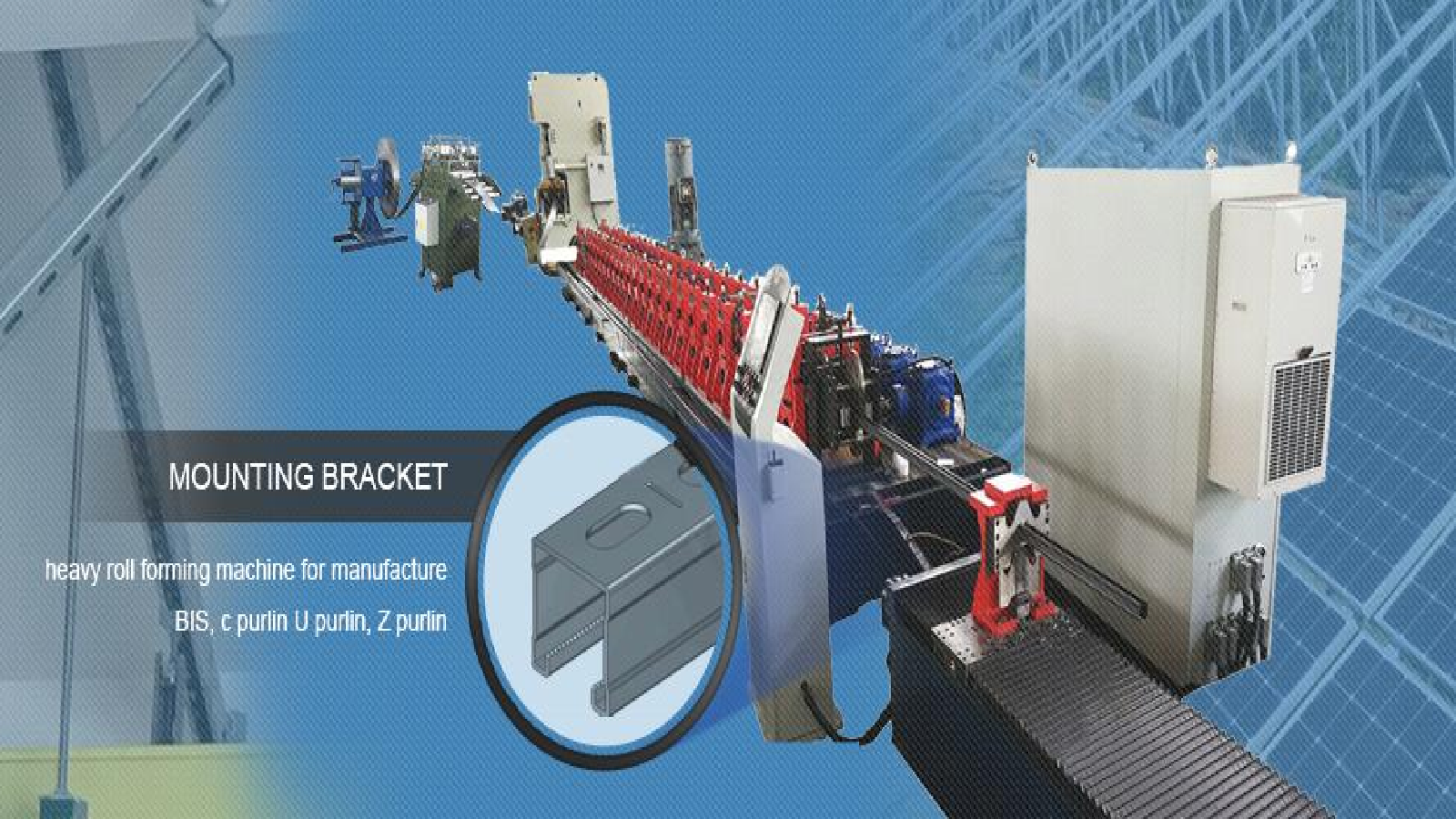

Production process:De-coiler →lever and feeder → press machine(contain punching die)→roll forming profile →cutting table →packing table (hydraulic system given power) all parts were control by electrical control system

C rack standing racking system upright machinery manufacturing roll forming machine | |||

| No | Item | Unit | Qty |

| 1.1 | Hydraulic de-coiler | No | 1 |

| 1.2 | Straightener | No | 1 |

| 1.3 | Servo feeder | No | 1 |

| 2.1 | Press machine Capacity is 125 ton | No | 1 |

| 2.2 | Punching die | No | 1 |

| 3 | C 38*40 roll forming machine Product speed 30-50m per min | No | 1 |

| 4 | Cutting unit,Speed 15-30M per min | No | 1 |

| 6 | Hydraulic system | No | 1 |

| 7 | Electric control system | No | 1 |

| 8 | Packing table | No | 1 |

Load capacity:4 ton with loading carriage Material : 2mm ,S 235 JR

Material width: 450MM

feed pitch accuracy is +-0.15mm, Brand of PLC is Mitsubishi Servo motor power is 2.9 kw, brand is YASKAWA

Capacity is 125 ton YANGLI JH21-125

1. Hydraulic pump flow:50L/min TAIWAN 2. Motor power:11KW;SIEMENS 3. Hydraulic solenoid value number:2set, SIHUA 4. Hydraulic accumulator capacity 30L 5、Tank volume:220L.

1. Encoder:OMRON(Japanese brand) 2. Frequency motor30KW(NIDEC)JAPAN 3. PLC:Siemens(German brand) 4. Human interface:Siemens 5. Relay: OMRON(Japanese brand)

1. Guide rail brand: TBI 2. Cylinder:ARITAC 4.cutter frame 1 unit 5.cutting unit base 6.Big oil cyclinder 7.cutting die 1sets and die frame .Material:SKD11 vacuum heat treatment

Product advantages

1.Easy to operate

2.High production speed

3.Stable and durable

4.Has a wide range of uses

DescriptionofstorageuprightrackrollformingmachineWeight:About30000KGSSize:25*3.5*2.9m(Length*Width*Height)RollerStations:18-22 (dependsOnFinalDesign)RollerShaftsDiameter:70mmRollFormingSpeed:15-25m/minFormingRollersMaterial:C

DescriptionofstorageuprightrackrollformingmachineWeight:About30000KGSSize:25*3.5*2.9m(Length*Width*Height)RollerStations:18-22 (dependsOnFinalDesign)RollerShaftsDiameter:70mmRollFormingSpeed:15-25m/minFormingRollersMaterial:C

profiles drawing

C RAIL material thickness 1.5-4.0mm

C RAIL material thickness 1.5-4.0mm

Production speed

Product speed is 40-45M- 30Mper min -20M/min Product thickness is 0.5-1mm-2.00mm-2.5.00mm

1.3 Product length tolerance L+-1mm

1.4 Total

profiles drawing

C RAIL material thickness 1.5-4.0mm

C RAIL material thickness 1.5-4.0mm

Production speed

Product speed is 40-45M- 30Mper min -20M/min Product thickness is 0.5-1mm-2.00mm-2.5.00mm

1.3 Product length tolerance L+-1mm

1.4 Total

profiles drawing

C RAIL material thickness 1.5-4.0mm

C RAIL material thickness 1.5-4.0mm

Production speed

Product speed is 40-45M- 30Mper min -20M/min Product thickness is 0.5-1mm-2.00mm-2.5.00mm

1.3 Product length tolerance L+-1mm

1.4 Tota

profiles drawing

C RAIL material thickness 1.5-4.0mm

C RAIL material thickness 1.5-4.0mm

Production speed

Product speed is 40-45M- 30Mper min -20M/min Product thickness is 0.5-1mm-2.00mm-2.5.00mm

1.3 Product length tolerance L+-1mm

1.4 Tota