Home > Struct Roll Forming Machine

Profiles drawing

C RAIL material thickness 1.5-4.0mm

Production speed

Product speed is 40-45M- 30Mper min -20M/min Product thickness is 0.5-1mm-2.00mm-2.5.00mm

Product length tolerance L+-1mm

Total power:45.4kw

Voltage: 380v 3-phase 50hz

Motor in roll forming machine:30KW*1PC

Motor in hydraulic station power is 11kw

Servo motor is 4.4kw

Introduction

Production process:

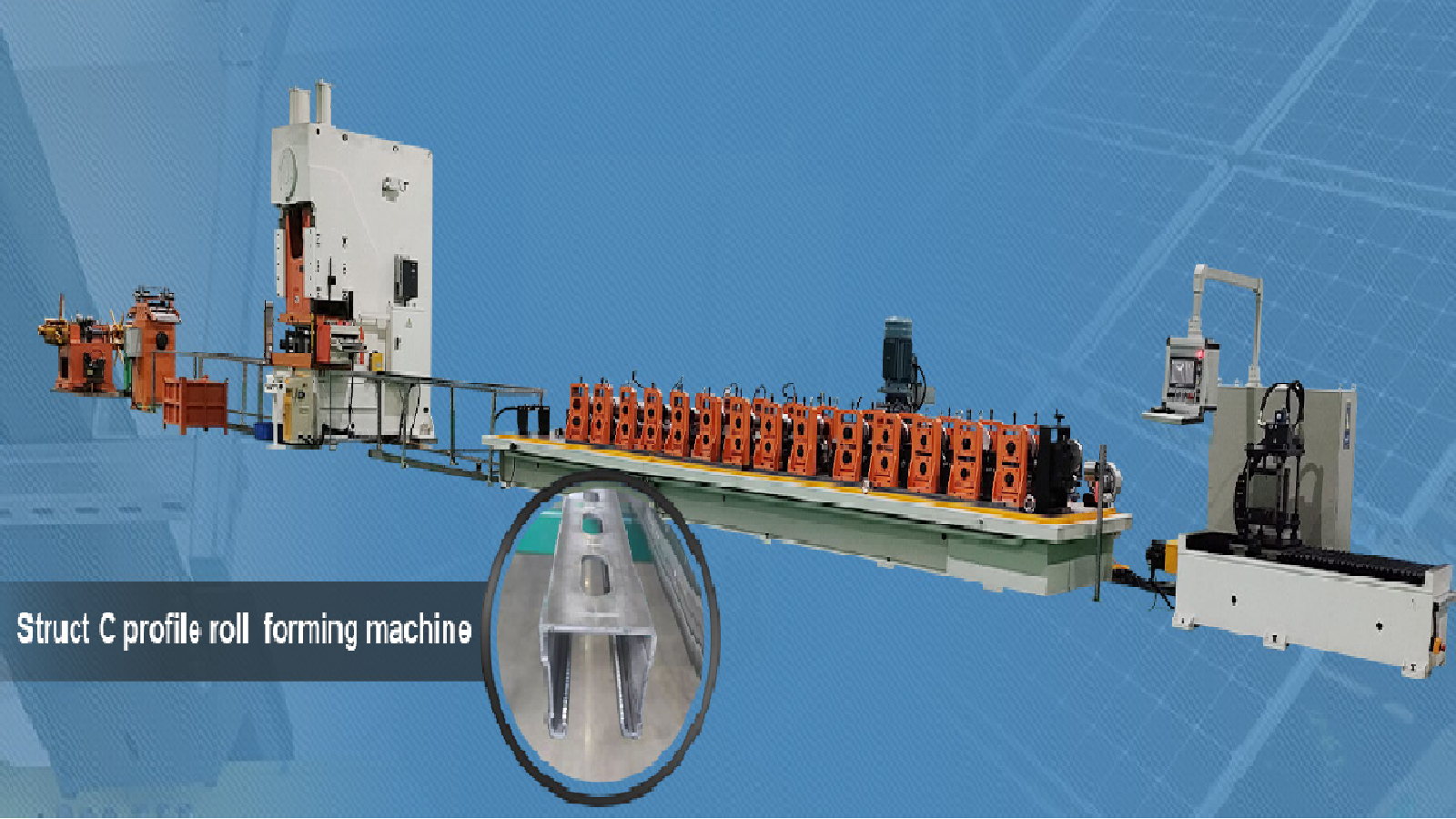

De-coiler →lever and feeder → press machine(contain punching die)→roll forming profile →cutting table →packing table (hydraulic system given power) all parts were control by electrical control system

| Quality and cheap C shaped steel struct channel roll forming machine | |||

| No | Item | Unit | Qty |

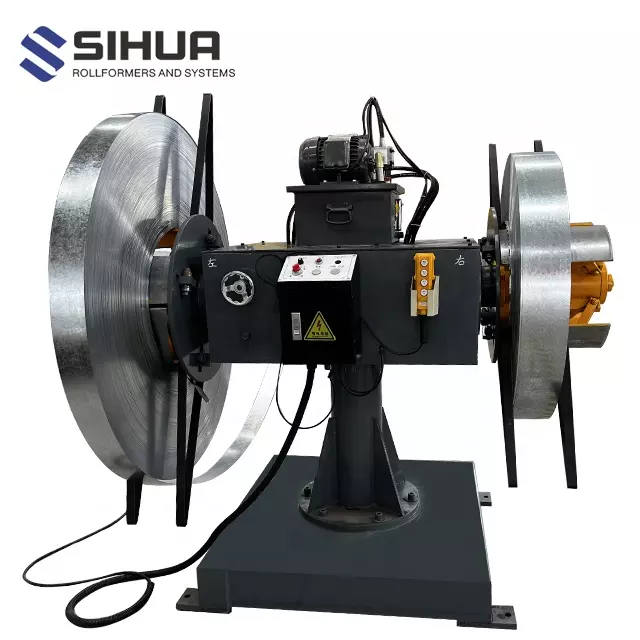

| 1.1 | Hydraulic de-coiler | No | 1 |

| 1.2 | Straightener | No | 1 |

| 1.3 | Servo feeder | No | 1 |

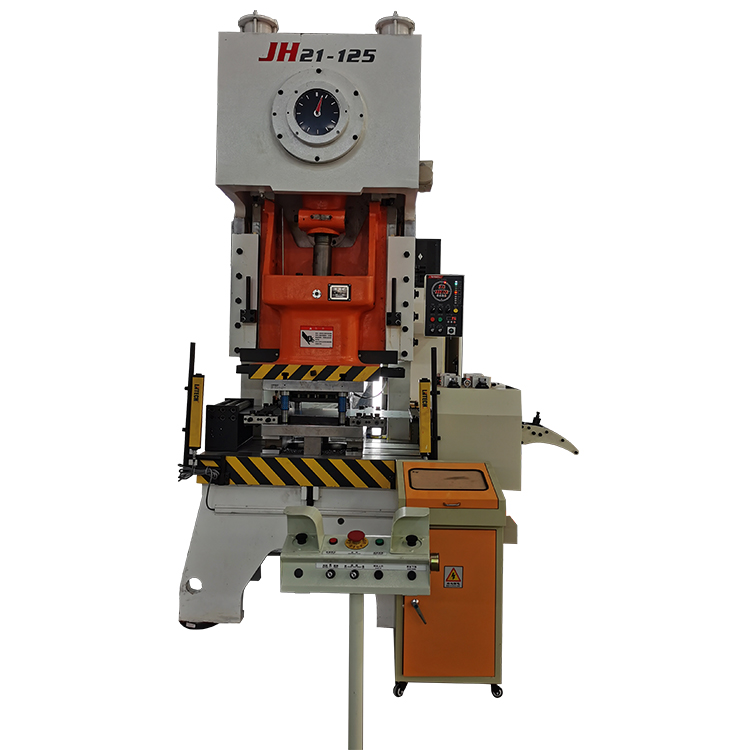

| 2.2 | Punching die | No | 1 |

| 3 | C 38*40 roll forming machine Product speed 30-50M per min | No | 1 |

| 4 | Cutting unit ,speed is 15-30M per min | No | 1 |

| 6 | Hydraulic system | No | 1 |

| 7 | Electric control system | No | 1 |

| 8 | Packing table | No | 1 |

Capacity is 3tons *2PC straightener

Yangli capacity 125tons YANGLI JH21-125

C 38*40 roll forming machine Product speed30-50m per min

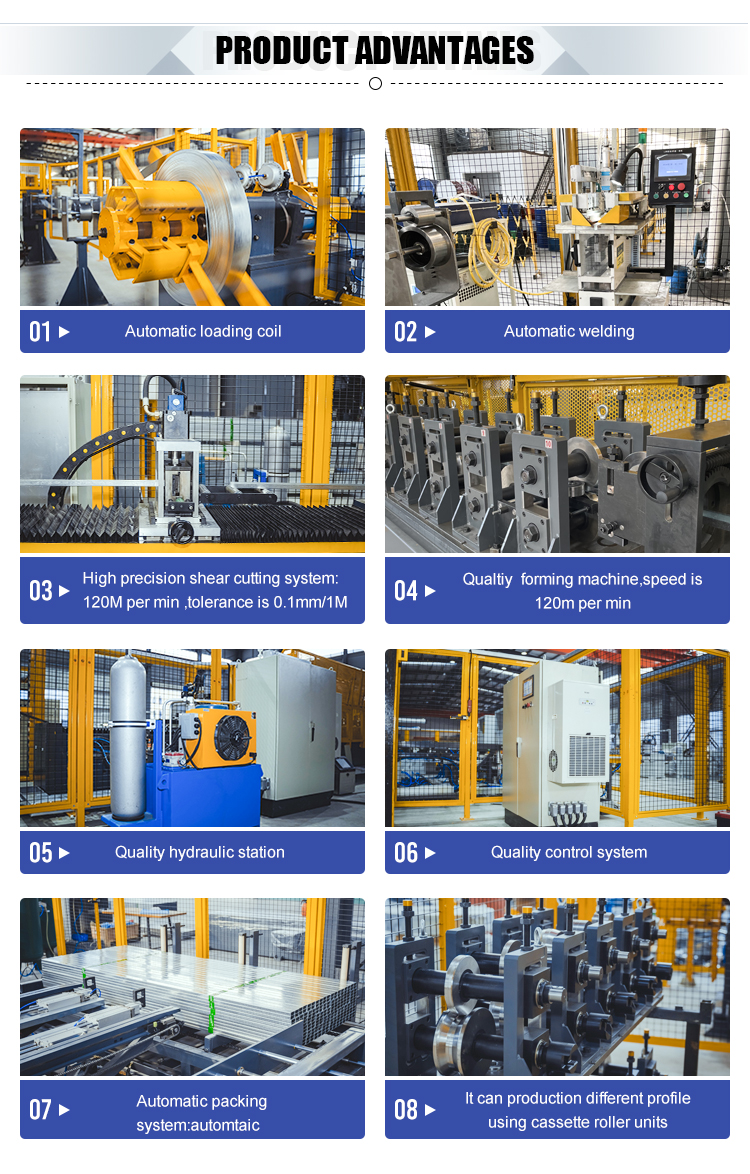

1. Encoder:OMRON(Japanese brand) 2. Frequency motor:45KW(NIDEC)JAPAN 3. PLC:MITSUBISHI(Japanese brand) 4. Human interface:KINCO 5. Relay: OMRON(Japanese brand)

Stacking table 6.5m

1. Easy to operate

2. High production speed

3. Stable and durable

4. Has a wide range of uses

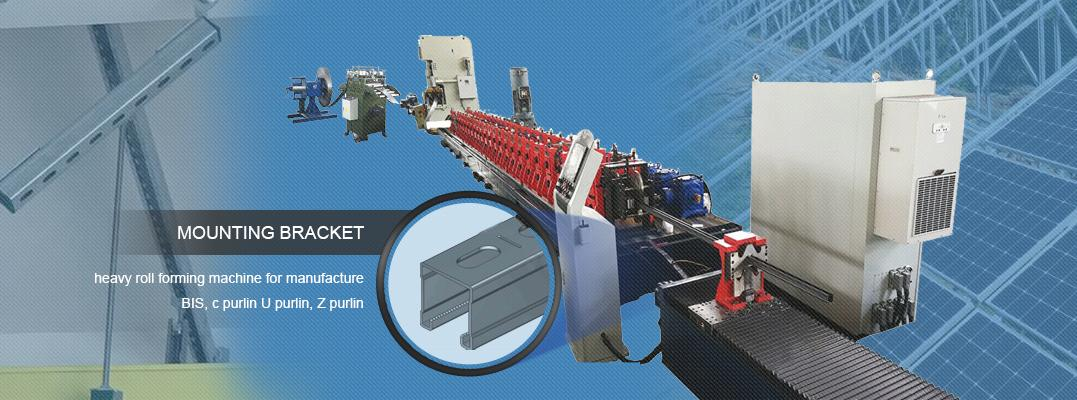

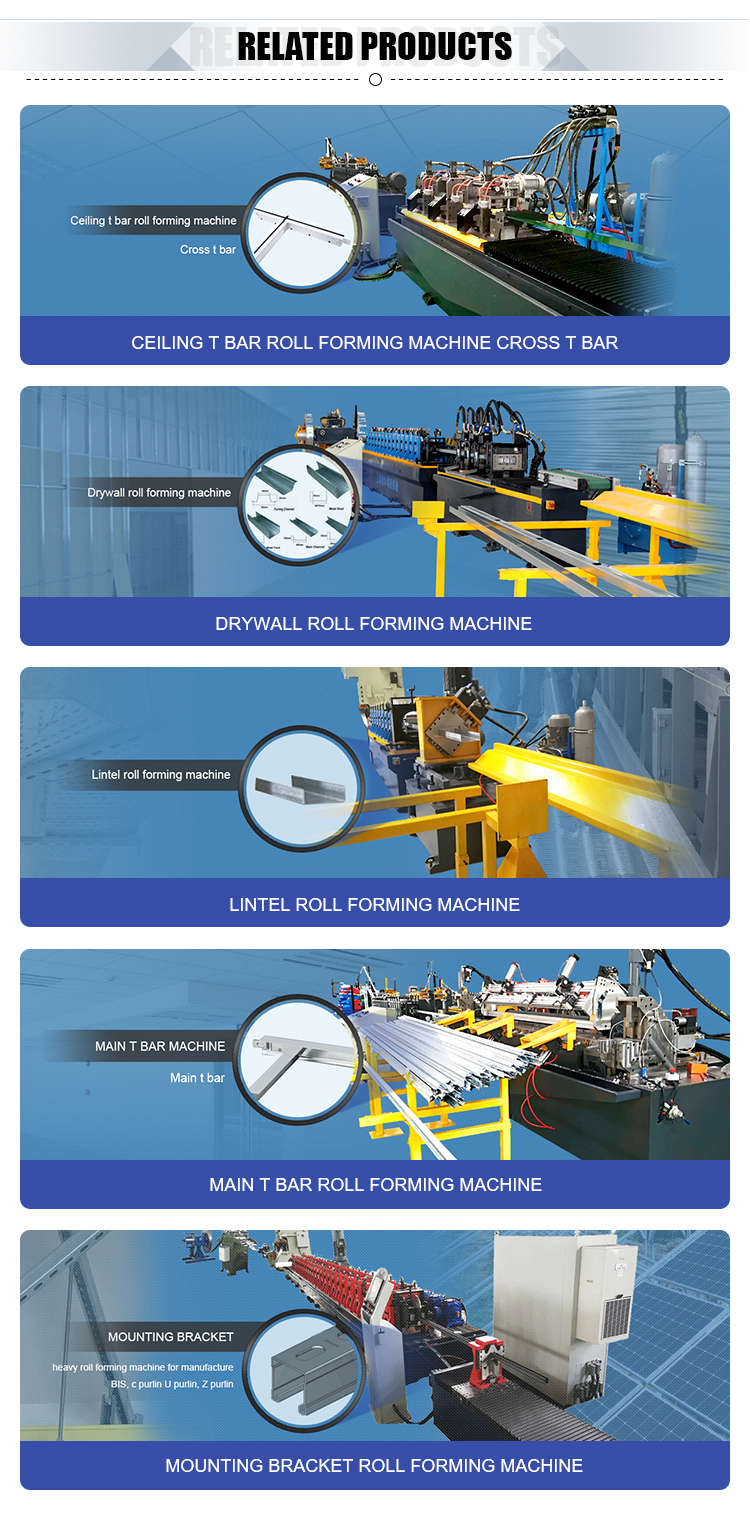

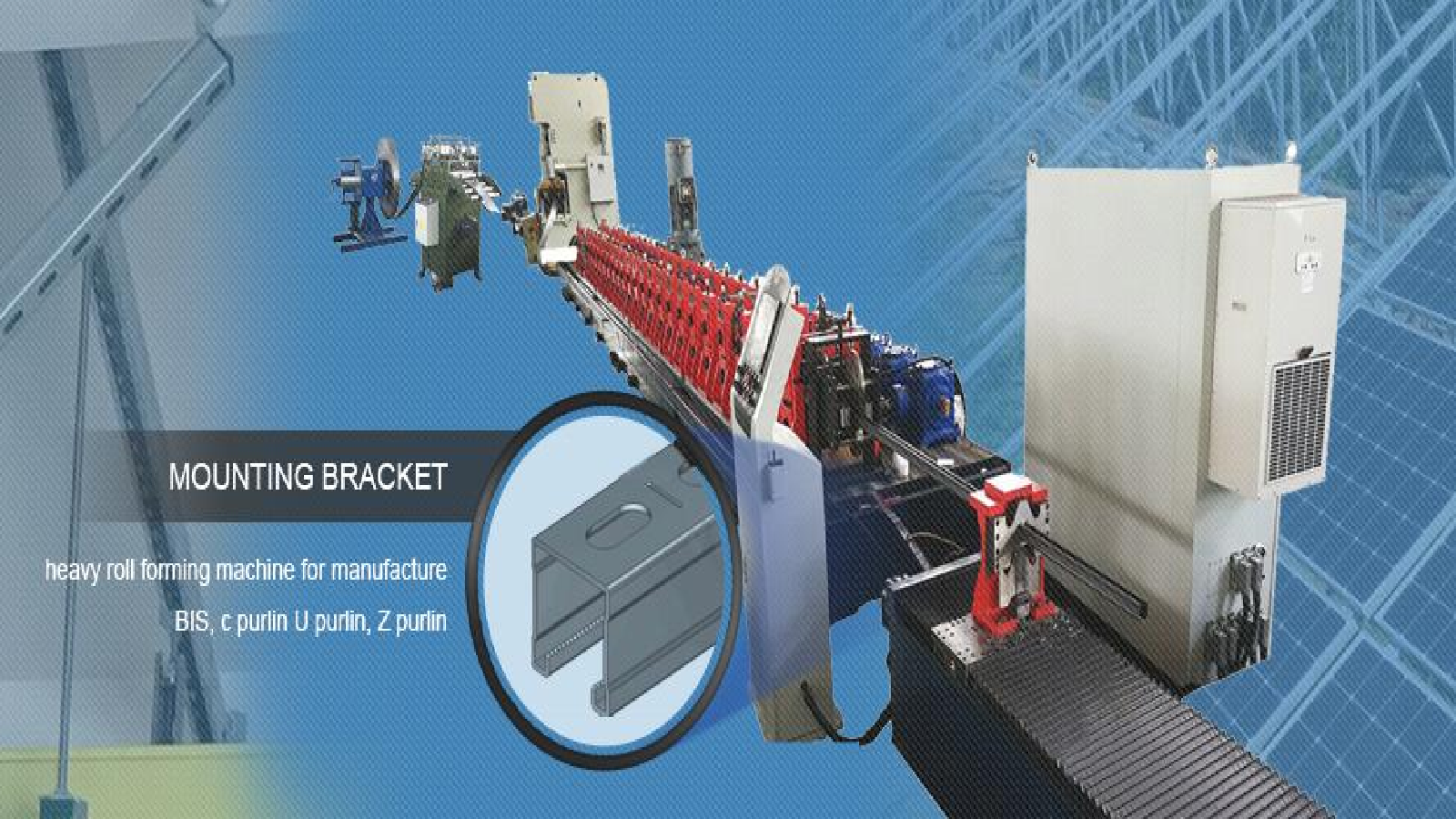

C Rail Strut roll forming machine, also known as the amounting bracket support roll forming machine, is developed on the basis of the seismic bracket roll forming machine. This product is used to install, support, support and connect lightweight structural loads in building construction.

SIHUA strut channel roll forming machine is suitable to produce strut profile sizes 41*41、41*51 、41*52、41*72 by manually changing different cassette rollers. One size of profile uses one type of cassette roller, which can save time in adjusting the roller and debugging time, and is easy for ordinary operators to operate.

The rail metal thickness is 12 gauge(2.6mm) or 14 gauge (1.9mm) (normally range 1.5-2.5mm). Raw material could be Hot-rolled or cold-rolled steel, Hot-dip galvanized sheet, Pre-Galvanized Steel, Mill(Plain/Black) Steel etc. According to slot type, our machine could produce solid channel, slotted channel, half slotted channel, long slotted channel, punched channel, punched and slotted channel etc.

41 X 21 / 41 X 41 41*56 41*72 Galvanized Unistrut Steel Slotted Strut Channel Roll Forming Machine

Solar frame panels are used to install, brace, support and connect lightweight structural loads in building construction. These include pipes, electrical and data wire, mechanical systems such as ventilation, air conditioning, and other mechanical systems. Strut channels are also used in other applications that require a strong frame, such as workbenches, racking systems, equipment racks, etc. Special sleeves can be used to tighten nuts; bolts, etc.

Solar Panel Frame Manufacturing machine Strut Rollforming Line C Solar Strut Channel Roll Forming Machine.

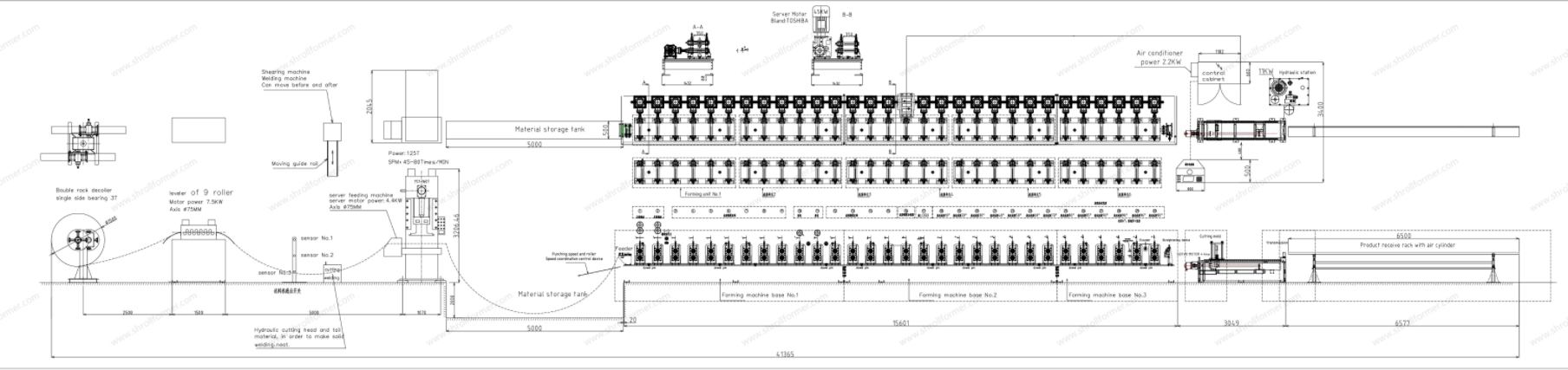

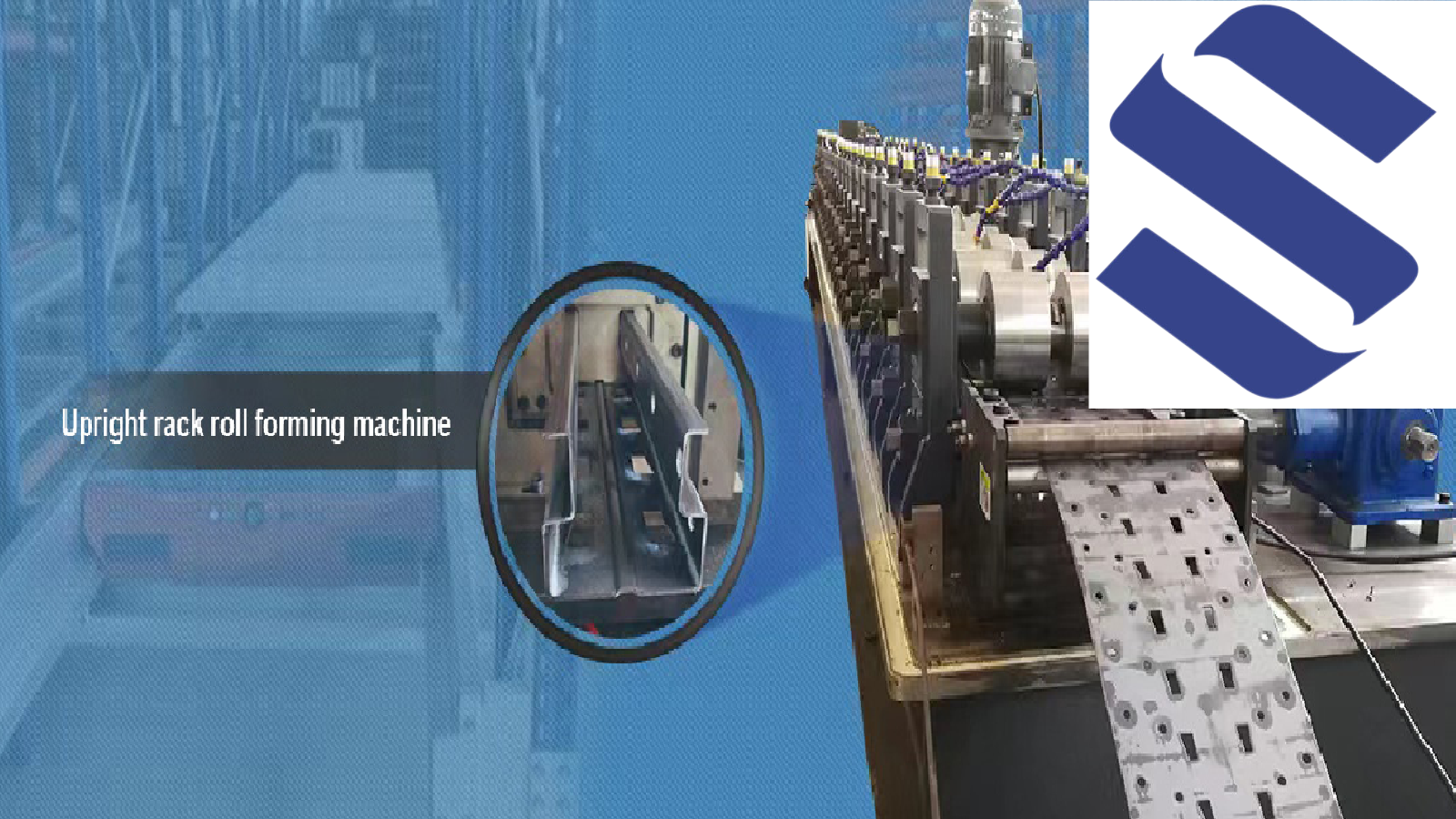

DescriptionofstorageuprightrackrollformingmachineWeight:About30000KGSSize:25*3.5*2.9m(Length*Width*Height)RollerStations:18-22 (dependsOnFinalDesign)RollerShaftsDiameter:70mmRollFormingSpeed:15-25m/minFormingRollersMaterial:C

DescriptionofstorageuprightrackrollformingmachineWeight:About30000KGSSize:25*3.5*2.9m(Length*Width*Height)RollerStations:18-22 (dependsOnFinalDesign)RollerShaftsDiameter:70mmRollFormingSpeed:15-25m/minFormingRollersMaterial:C

profiles drawing

C RAIL material thickness 1.5-4.0mm

C RAIL material thickness 1.5-4.0mm

Production speed

Product speed is 40-45M- 30Mper min -20M/min Product thickness is 0.5-1mm-2.00mm-2.5.00mm

1.3 Product length tolerance L+-1mm

1.4 Total

profiles drawing

C RAIL material thickness 1.5-4.0mm

C RAIL material thickness 1.5-4.0mm

Production speed

Product speed is 40-45M- 30Mper min -20M/min Product thickness is 0.5-1mm-2.00mm-2.5.00mm

1.3 Product length tolerance L+-1mm

1.4 Total

profiles drawing

C RAIL material thickness 1.5-4.0mm

C RAIL material thickness 1.5-4.0mm

Production speed

Product speed is 40-45M- 30Mper min -20M/min Product thickness is 0.5-1mm-2.00mm-2.5.00mm

1.3 Product length tolerance L+-1mm

1.4 Tota

profiles drawing

C RAIL material thickness 1.5-4.0mm

C RAIL material thickness 1.5-4.0mm

Production speed

Product speed is 40-45M- 30Mper min -20M/min Product thickness is 0.5-1mm-2.00mm-2.5.00mm

1.3 Product length tolerance L+-1mm

1.4 Tota