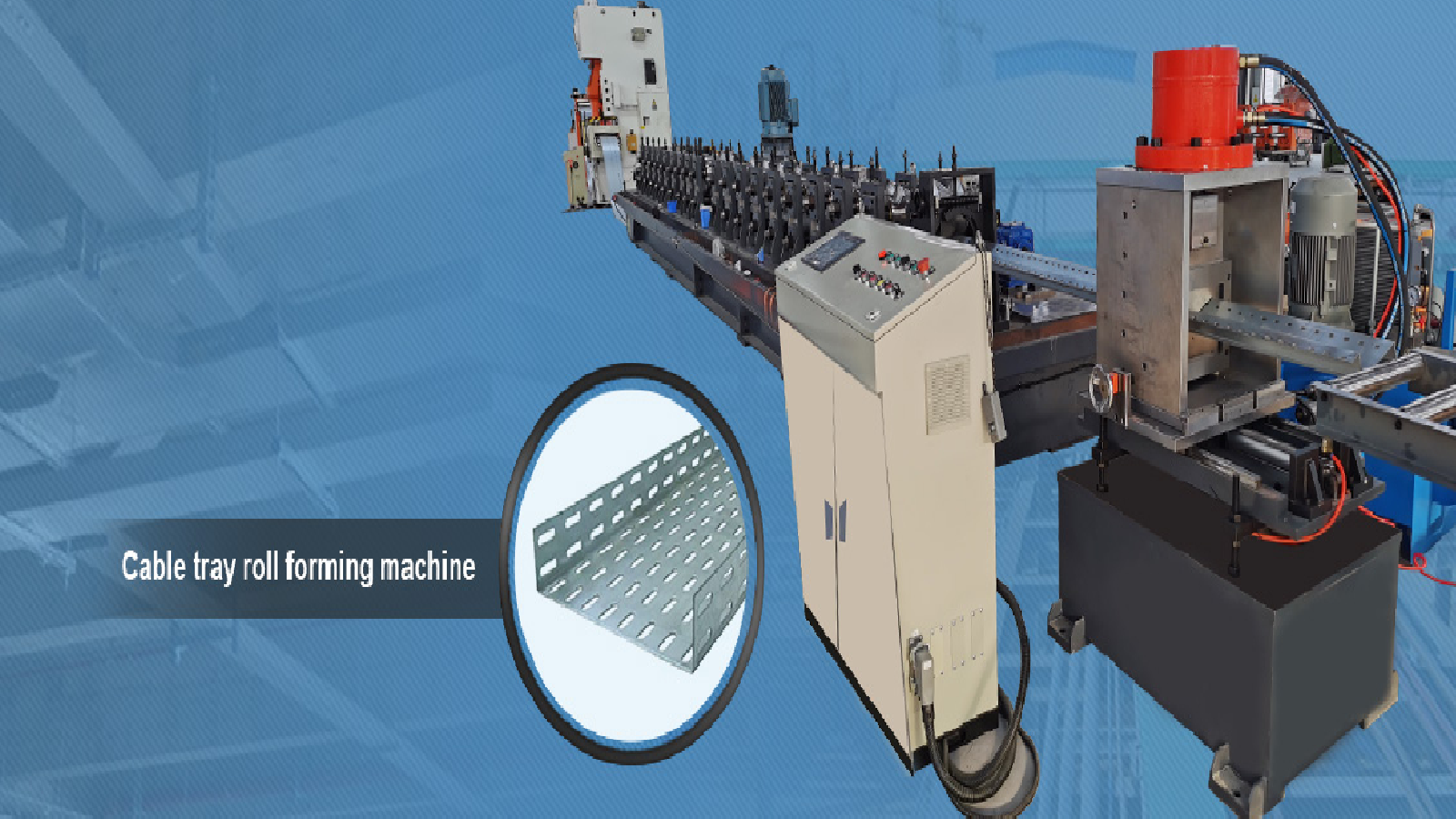

Home > Cable Tray Roll Forming Machine

1.1 product speed is up to punching capacity

1.2 product length tolerance 0.3mm per 3M

1.3 total motor power: 87kw(5.5+45+5.5+11kw+20kw)

1.4 production line length and width:30Meter and 2Meter

Introduction

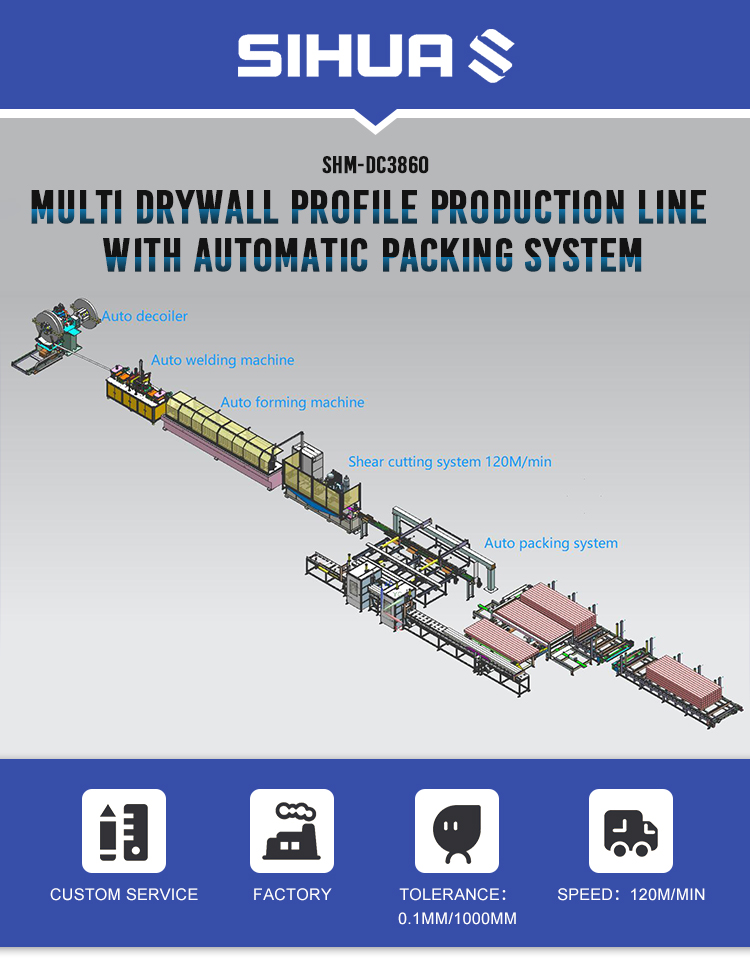

Production process:decoiler→straightener→ servo feeder→press machine→straightener→cutting table→stacking table (hydraulic system give power) all parts were control by electrical control system

| Sihua Popular high speed Cable Tray Roll Forming Making Machine | |||

| No | Item | Unit | Qty |

| 1.1 | Heavy decoiler | No | 1 |

| 1.2.1 | Straightener | No | 1 |

| 1.2.2 | Feeder | No | 1 |

| 2.1 | Press machine | No | 1 |

| 2.2 | Punching mold | No | 1 |

| 3.1 | Cable tray Roll forming machine | No | 1 |

| 3.2 | Automatic control width system | No | 1 |

| 4 | Shearing and low speed Cutting off machine | No | 1 |

| 5 | Hydraulic system | No | 1 |

| 6 | Electric control system | No | 1 |

| 7 | Packing table | No | 1 |

| 8 | Transport fee And insurance fee | No | 1 |

Un-coiler: Load capacity:5 ton Material width《100MM hydraulic expansion

1.YANGLI JH21-250 Capacity:250ton 2.Commissioning 3.Hydraulic oil Transportation charge

3.1, Roll former steps is 22 steps Roller material: Cr12MoV, 58-62 HRC by vacuum heat treatment. 3.2 stand rollers steps is 5 steps Roller material :cr12mov 58-62HRC by vacuum heat treatment. 3.3, Motor power: 45 KW, Brand is ABB 3.4, Motor driven connect with reducer to drive gear box 3.5, Shaft core diameter is ∮70mm ,material is 40 CR by quenching high temperature tempering

1.Hydraulic pump flow:60L/min 2.Motor power:22KW;brand is siemens 3.Oil cooling by air 4.Hydraulic solenoid value ,SIHUA(German) 4. Hydraulic accumulator capacity 15L 5.Tank volume:220L. 6. Pressure sensor: IFM(German)

1.Encoder:OMRON(Japan brand) 2.Frequency inverter:45KW TECO(Taiwan) 3.PLC: MITSUBISHI(Japan brand) 4.Human interface:KINCO 5.Relay and breaker:SIHUA(German brand)

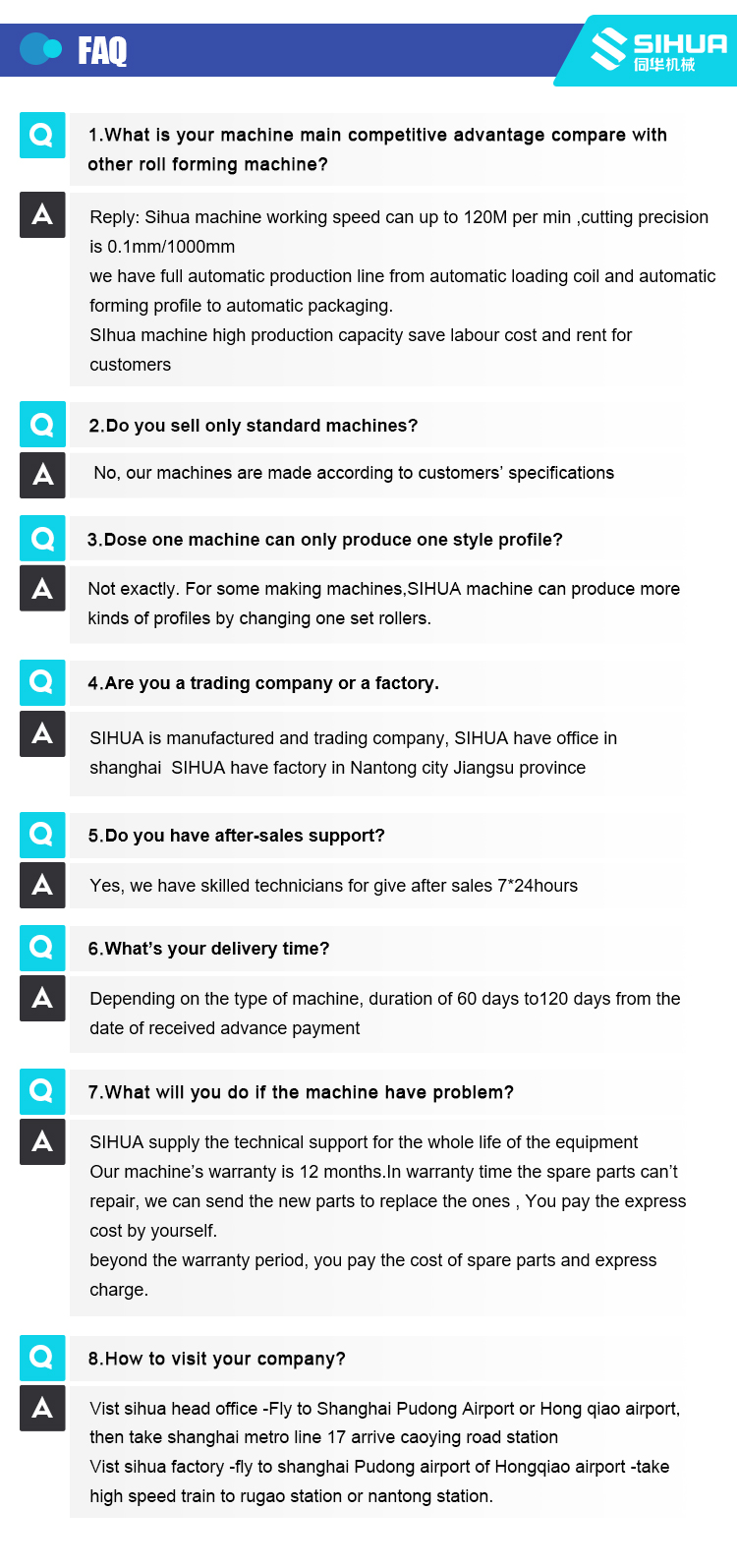

1. Easy to operate

2. High production speed

3. Stable and durable

4. Has a wide range of uses

Automatic change width:50-600mm

Automatic change height:50-150mm

ShanghaiSihuaPrecisionMachineryCo.,Ltdfocusonresearchinganddevelopingrollformingtechnologyandinnovationforautomatichigh-speedflyingshearrollformingmachine.ShanghaiSIHUAhasanexcellentresearchteam,wecanachieveatleast

ShanghaiSihuaPrecisionMachineryCo.,Ltdfocusonresearchinganddevelopingrollformingtechnologyandinnovationforautomatichigh-speedflyingshearrollformingmachine.ShanghaiSIHUAhasanexcellentresearchteam,wecanachieveatleast

DescriptionofCableTrayIndustryFormingMachinesTheperforatedCableTrayRollFormingMachineisaduplexandhighperformanceproductionlineformanufactureCsectionprofilewithslottedholesforsupportingelectricwiringincommercialandi

DescriptionofCableTrayIndustryFormingMachinesTheperforatedCableTrayRollFormingMachineisaduplexandhighperformanceproductionlineformanufactureCsectionprofilewithslottedholesforsupportingelectricwiringincommercialandi

lintelprofileusingforconstructionwork

lintelprofileusingforconstructionwork