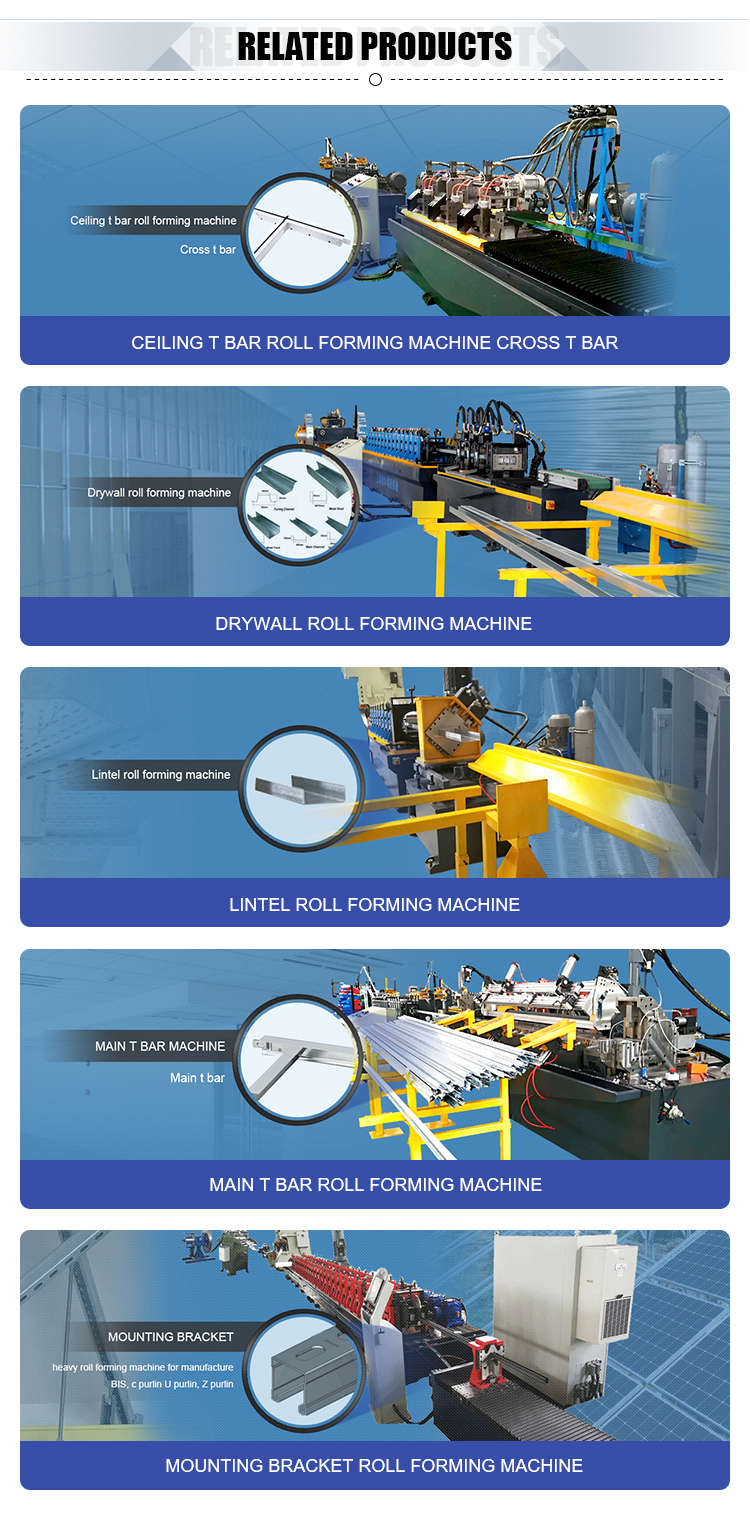

Home > Ceiling T Bar Roll Forming Machine

This video recorded the testing of Alloy connector Cross t bar Roll Forming Machine.

Products produced by this machine are widely used in support and hanger system.

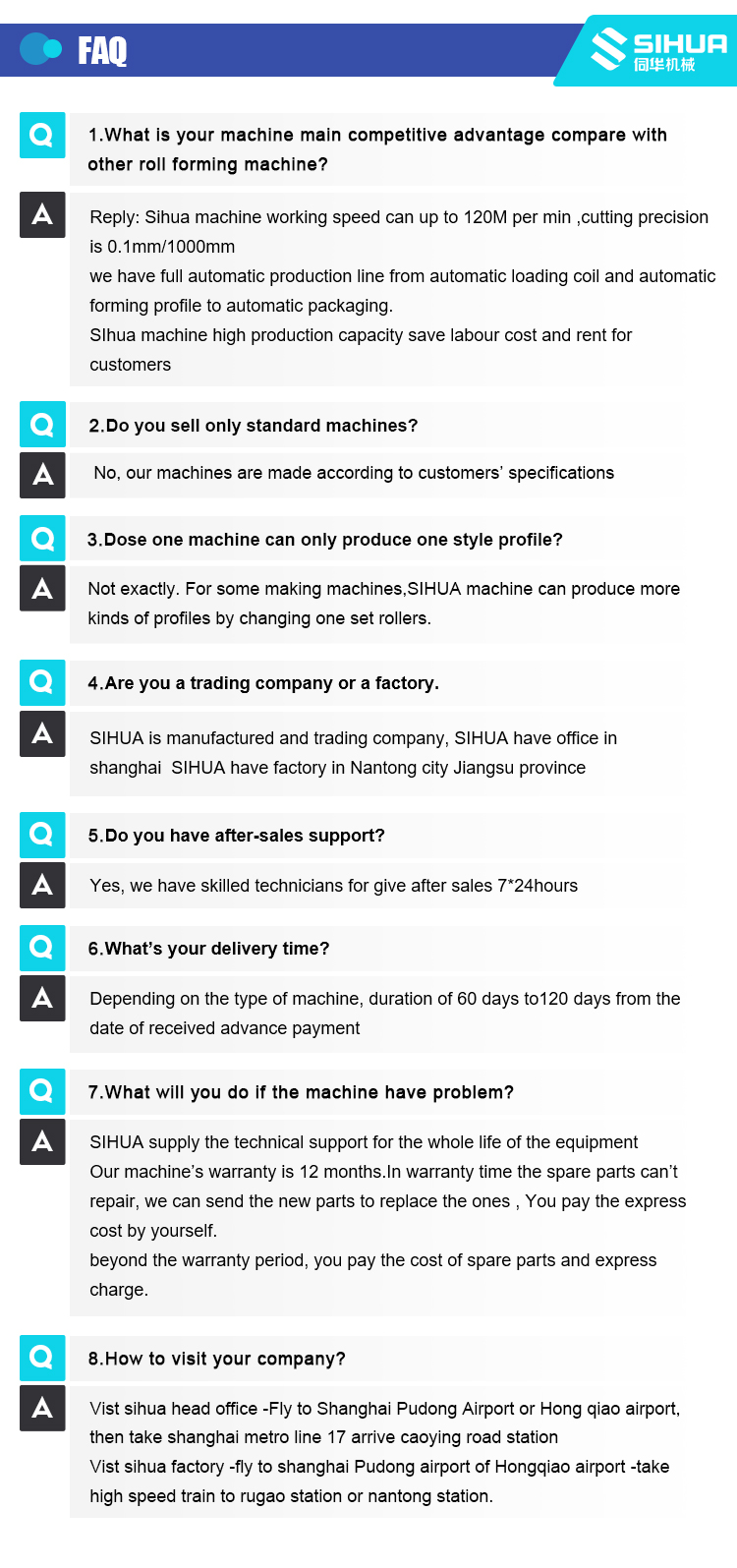

SIHUA experts in Roll Forming Machine and Manufacturing, provide Roll Forming Equipment in variety of industries.

We are committed to providing you with high quality complete metal roll forming solutions.

Applicable Industries | Building Material Shops, Machinery Repair Shops, Construction works |

Video outgoing-inspection | Provided |

Machinery Test Report | Provide product quality inspection reports |

Warranty of core components | 3 years |

Warranty of other components | 1 year |

Place of Origin | Jiangsu, China |

Brand Name | SIHUA |

Product Name | T Grid Roll Forming Machinery |

Feature | high production speed |

Control System | fully automatic |

Raw Material | Galvanized Sheet/ PPGI |

Life Time | At least 5 years |

Collocation recommendation | We recommend you purchase our Automatic metal profile packaging machine to make your production more orderly |

1. Easy to operate

2. High production speed

3. Stable and durable

Machine parameter | ||||

Model | Product | Max production speed | sheet thickness | Hook type |

SHM-DACT30 | Cross T | 30m/min | 0.3-0.8mm | Alloy hook |

Machine name: Alloy connector SIHUA Cross-T bar production line.

Automatic high speed high precision long and short cross t bar roll forming machine

Product sizes

1. 25H*24*1220mm(4`)/1200

2. 25H*24*610mm(2`)/600

We design the machine do according to your confirmed drawing

Machine Introduction

1.1 T-Bar production line can be monitored by PLC. If the T-bar production line has errors, the PLC will locate the errors. It is easy to maintenance for workers.

1.2 Cross T-Bar Production speed :

1.2.1 4`=38M/MIN (1 minute to produce 30PC).

1.2.2 2`=33M/MIN (1 minute to produce 52PC).

1.3 The machine can produce product specifications: 26*24cross-T.

Different spcifications exchange cassette rollers can be replaced in 30 minutes

For example: 26H *24 specifications can be produced if add one set exchange cassette rollers

1.4 Electric power: 25kw

Voltage: 380v/400v/415v 3-phase 50/60hz or as custom need

Annoy connector cross t bar profile

Roll forming machine

Shearing cutting off system

NO. | Part Names | Quantity |

1 | Double de-coiler (paint steel coil) | 1 |

2 | Storage unit for paint steel. | 1 |

3 | Double de-coiler (galvanized steel coil) | 1 |

4 | Roll former base. | 1 |

5 | T-bar roller forming working units. With reducer interchange roller | 1 |

6 | Cutting table base | 1 |

7 | Punching dies. | 1 |

8 | Packaging platform | 1 |

9 | Control panel (Electric control system) | 1 |

10 | Hydraulic installations | 1 |

Product drawing:

Main t bar profile 38h *24*3600mm、/3700mm

Cross t bar profile 38h*24*600/1200mm

Product drawing:

Main t bar profile 38h *24*3600mm、/3700mm

Cross t bar profile 38h*24*600/1200mm

Ceiling Main T bar roll forming machine

Ceiling Main T bar roll forming machine

Machinename:SIHUACross-Tbarproductionline.Automatichigh speed high precision longandshortcrosstbarrollformingmachineProductsizes1. 25H*24*1220mm(4`)/12002. 25H*24*610mm(2`)/600 Wedesign

Machinename:SIHUACross-Tbarproductionline.Automatichigh speed high precision longandshortcrosstbarrollformingmachineProductsizes1. 25H*24*1220mm(4`)/12002. 25H*24*610mm(2`)/600 Wedesign