Home > Ceiling T Bar Roll Forming Machine

Applicable Industries | Building Material Shops, Machinery Repair Shops, Construction works |

Video outgoing-inspection | Provided |

Machinery Test Report | Provide product quality inspection reports |

Warranty of core components | 3 years |

Warranty of other components | 1 year |

Place of Origin | Jiangsu, China |

Brand Name | SIHUA |

Product Name | Alloy hook connector Cross t bar roll forming machine |

Feature | high production speed |

Control System | fully automatic |

Raw Material | Galvanized Sheet/ PPGI |

Life Time | At least 5 years |

Collocation recommendation | We recommend you purchase our Automatic metal profile packaging machine to make your production more orderly |

1.1 Loading capacity :1500Kgs*2 1.2. Max coil specification: O.D. 2,000 mm. I.D. 508 mm. Plate width: 100 mm. 1.3. By hydraulic rolling to tighten the coil.

1.3.1 Loading capacity :3000 KGS*2 1.3.2. Max coil specification: O.D. 1,500 mm. I.D.508 mm. Width: 150 mm. 1.3.3. By hydraulic rolling in to tighten the coil.

2.1.1 Siemens motor, power is 15KW 2.1.2 Cross T bar gear box unit (COMBI) 2.1.3 The machine base material is Q345-B steel by heat treatment to eliminate inner force for long machine life, like box structure 2.1.4 The machine working table uses large CNC whole processing for high precision flat, flat tolerance within 0.05mm. The distance between the roller forming machine and locating pin within 0.02mm 2.1.5 COMBI are fixed on the base. It can be exchange according to different sizes

3.1.1. Punching dies use the material of DC53 with vacuum heat treatment Hardness is HRC 58 – 62 3.1.2. Installed 3 pieces punching dies (detail as punching dies) the distance between punching dies can be adjusted 3.1.3. Cut-off length 1200mm/600mm T-BAR mounting holes 、Connector by hydraulic punching, 3.1.4 The servo motor power: 7.5 KW. Brand: Yaskaya (Japan) 3.1.5 Ball screw and guide rail brand: THK 3.1.6. The machine base material is Q345-B steel by heat treatment to eliminate inner force for long machine life 3.1.7. The machine working table uses large CNC whole processing for high precision flatness, flatness tolerance within 0.05mm.

There are 2 sets de-coiler for alloy coil Alloy coil size :ID:250-320mm OD:800-1000mm Width:18.1 mm thickness 0.3-0.4mm

5.1, Motor power: 15KW, Motor brands:SIEMENS Inovance. 5.2, Hydraulic Pump Brand is REXROTH (Germany). 5.3, oil cylinders, quantity: 6 pieces 5.4, Accumulator:40L Brand: OLAER(French) 5.5, Pressure sensor, IFM (German) 5.6 The magnetic valve: Rexroth 24V (German). 5.7 Filtration brand is Parker (USA) 5.8, The oil is cooled by air

6.1, PLC brands: MITSUBISHI (JAPAN). 6.2, Frequency invertor power:15 KW brand: YASKAWA 6.3, Relay and breaker brand: SCHNEILDER 6.4, Human interface (touch screen) brand: KINCO, size 10.4 ". 6.5, Electric cabinet, uses the quick plug to connect outside wire. 6.6. Shear controller, brand: SI HUA (import from German). 6.7 Encode is OMRON

Length is 1.2M High is 1M

1. Easy to operate

2. High production speed

3. Stable and durable

4. Has a wide range of uses

Machine name: Alloy connector SIHUA Cross-T bar production line

Automatic high speed high precision long and short cross t bar roll forming machine

Product sizes

1. 25H*24*1220mm(4`)/1200

2. 25H*24*610mm(2`)/600

We design the machine do according to your confirmed drawing

Machine Introduction

1.1 T-Bar production line can be monitored by PLC. If the T-bar production line has errors, the PLC will locate the errors. It is easy to maintenance for workers.

1.2 Cross T-Bar Production speed:

1.2.1 4`=38M/MIN (1 minute to produce 30PC).

1.2.2 2`=33M/MIN (1 minute to produce 52PC).

1.3 The machine can produce product specifications: 26*24cross-T.

Different spcifications exchange cassette rollers can be replaced in 30 minutes

For example: 26H *24 specifications can be produced if add one set exchange cassette rollers

1.4 Electric power: 25kw

Voltage: 380v/400v/415v 3-phase 50/60hz or as custom need

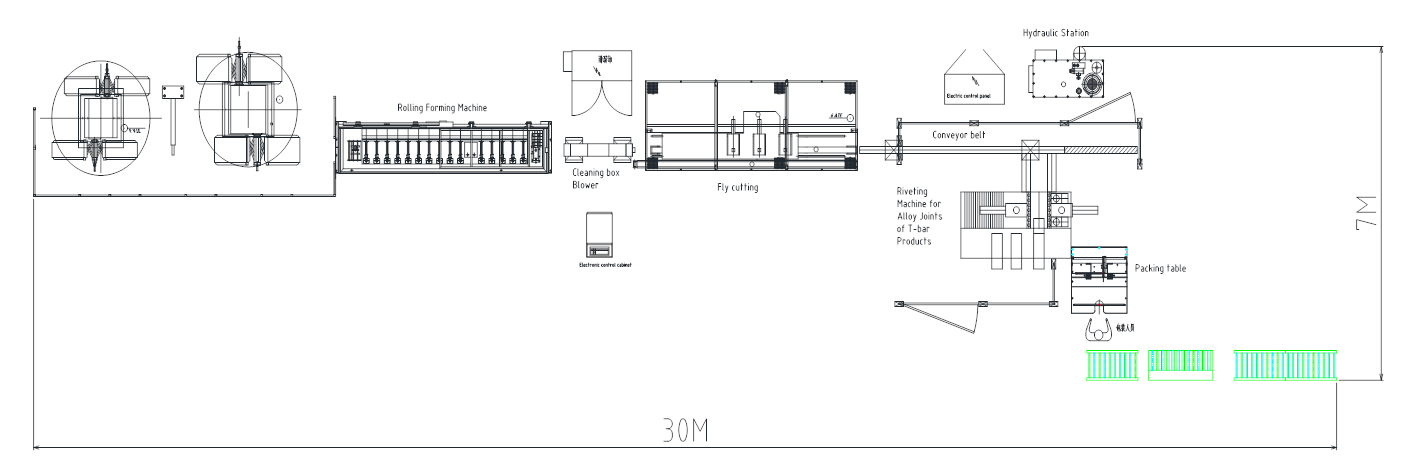

Machine layout:

T-Bar production line consists of the following components:

1. Double hydraulic de-coiler (paint steel coil)

2. Storage unit for paint steel

3. Double hydraulic de-coiler (galvanized steel coil)

4. Roll former unit of base

5. Cross T-bar roller forming units (COMBI)

6. Triple sizes profile cleaning unit.

7. Cutting table base

8. Cutting dies

9. Riveting machine for Alloy joints of T-bar Products

10. Packaging platform

11. Control panel (Electric control system)

12. Hydraulic installations

A | Alloy hook 38*24 30*24 cross T bar machine SHM-DCT80-R | |

NO. | Part Names | Quantity |

1.1 | Double hydraulic de-coiler with wagon(paint steel coil) | 1 |

1.2 | Storage unit for paint steel. | 1 |

1.3 | Double hydraulic motor de-coiler with wagon (galvanized steel coil) | 1 |

2.1 | Forming machine base. | 1 |

2.2 | Cross T-bar roller unit With gear COMBI drive system One set combi for 38H*24*1200mm One set combi for 30H*24*600mm | 2 |

2.3 | Pitting spots roller unit | 1 |

3.1 | Servo shear cutting table base | 1 |

3.2 | Cross t bar profile Punching dies. | 1 |

4 | Cross t bar Packaging platform | 1 |

5 | Rexroth pump Hydraulic station | 1 |

6 | Big PLC Control panel (Electric control system) | 1 |

7 | safe fence for 1-5 and safe system | 1 |

B | Riveting machine for cross t bar Machine | |

NO. | Part Names | Quantity |

2.1 | Riveting machine for Alloy hook of 1200 cross T-bar Products | 1 |

2,2 | Rexroth pump Hydraulic station | 1 |

2.3 | Punching die | 2 |

2.4 | Riveting die | 2 |

2.5 | Feeder | 2 |

2.6 | Decoiler | 2 |

Annoy connector cross t bar profile

Roll forming machine

Shearing cutting off system

NO. | Part Names | Quantity |

1 | Double de-coiler (paint steel coil) | 1 |

2 | Storage unit for paint steel. | 1 |

3 | Double de-coiler (galvanized steel coil) | 1 |

4 | Roll former base. | 1 |

5 | T-bar roller forming working units. With reducer interchange roller | 1 |

6 | Cutting table base | 1 |

7 | Punching dies. | 1 |

8 | Packaging platform | 1 |

9 | Control panel (Electric control system) | 1 |

10 | Hydraulic installations | 1 |

SIHUA PRECISION MACHINERY CO.,LTD Located in SHANGHAI CHINA, is a professional manufacturer who focus on researching and developing automatic high-speed flying shear roll forming machines.

SIHUA was rated as one of the top 10 high-tech enterprises in Shanghai. SIHUA already have 42 innovative designs and 11 invention patents. We are committed to being the premier supplier of AUTOMATIC ROLL FORMING MACHINE.

SIHUA is headquartered in Qingpu District, Shanghai, and our factory is located in Nantong City, Jiangsu Province. We sincerely welcome you to visit our factory and learn more about our processing technology and quality details.

Product drawing:

Main t bar profile 38h *24*3600mm、/3700mm

Cross t bar profile 38h*24*600/1200mm

Product drawing:

Main t bar profile 38h *24*3600mm、/3700mm

Cross t bar profile 38h*24*600/1200mm

Ceiling Main T bar roll forming machine

Ceiling Main T bar roll forming machine

Machinename:SIHUACross-Tbarproductionline.Automatichigh speed high precision longandshortcrosstbarrollformingmachineProductsizes1. 25H*24*1220mm(4`)/12002. 25H*24*610mm(2`)/600 Wedesign

Machinename:SIHUACross-Tbarproductionline.Automatichigh speed high precision longandshortcrosstbarrollformingmachineProductsizes1. 25H*24*1220mm(4`)/12002. 25H*24*610mm(2`)/600 Wedesign